| |

|

| |

|

|

|

|

|

| |

|

What is SMT in High Frequency PCB ? |

|

|

|

| |

|

1.Definition and Purpose of SMT |

|

|

|

| |

|

In modern electronic devices, the design and manufacturing of high-frequency PCBs are crucial, and Surface Mount Technology (SMT) is key to enhancing high-frequency PCB performance. SMT is a technique that mounts electronic components directly on the surface of the PCB rather than through holes, which improves component density and electromagnetic compatibility, thereby enhancing the stability of high-frequency signal transmission. |

|

|

| |

|

|

|

|

| |

|

2. Changes and Advantages of SMT |

|

|

| |

|

How does SMT change high-frequency PCB manufacturing?

SMT not only increases component density but also significantly improves electromagnetic compatibility, making high-frequency signal transmission more stable. In the design of high-frequency PCBs, the advantages of SMT are particularly evident. By reducing the distance between components and improving signal paths, SMT can minimize signal loss. Additionally, SMT processes enable the design of smaller and more efficient PCBs, meeting today's demand for compact electronic devices. |

|

|

| |

|

|

|

|

| |

|

3. Necessity of SMT |

|

|

| |

|

In high-frequency applications, why is SMT indispensable for high-frequency PCBs?

|

|

|

| |

|

|

|

|

| |

|

3.1 Improving Manufacturing Efficiency |

|

|

| |

|

The introduction of this technology has gradually replaced traditional through-hole techniques, resulting in higher manufacturing efficiency and lower costs. Through precise automation processes, SMT can quickly and reliably produce high-quality high-frequency PCBs. |

|

|

| |

|

|

|

|

| |

|

3.2 Enhancing Signal Integrity |

|

|

| |

|

At the same time, SMT is essential for maintaining signal integrity. It significantly enhances signal integrity in high-frequency PCBs by reducing parasitic effects, improving signal paths, enhancing grounding, increasing component density, and ensuring proper thermal management. These factors collectively contribute to the reliability and efficiency of high-frequency circuit performance. |

|

|

| |

|

|

|

|

| |

|

4. Advantages of Taconic TLX-9 in SMT Applications |

|

|

| |

|

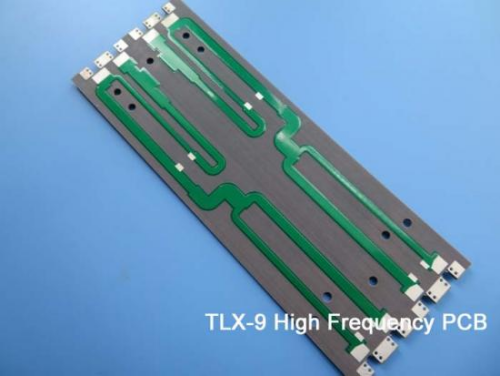

Regarding the application of Taconic PCBs in SMT, I like the TLX series the most, especially TLX-9 high-frequency PCB, which shows outstanding advantages.

Taconic TLX-9 PCB is a dimensionally stable PTFE fiberglass laminate, ideal for low layer count microwave designs. It is frequently utilized in single-layer and double-layer boards.The surface finishes primarily include bare copper, HASL, immersion gold, and immersion silver. Now let us explore its advantages in SMT applications. |

|

|

| |

|

|

|

|

| |

|

4.1 Excellent electrical performance parameters |

|

|

| |

|

At 10 GHz, TLX-9 substrate offers a low and stable dielectric constant of 2.500 ± 0.04, with a loss factor as low as 0.0019.It presents a high dielectric breakdown strength, which can ensure the integrity and transmission efficiency of signals at high frequencies. |

|

|

| |

|

|

|

|

| |

|

4.2 Good environmental adaptability |

|

|

| |

|

TLX-9 laminate features an extremely low moisture absorption rate, less than 0.02%. It can work stably even in environments with large humidity changes. Moreover, it has excellent electrical insulation properties, with high volume resistivity and surface resistivity, and strong arc resistance. |

|

|

| |

|

|

|

|

| |

|

4.3 Reliable mechanical properties |

|

|

| |

|

TLX-9 PCB material exhibits relatively high flexural strength and peel strength, as well as good dimensional stability. It is not easy to deform during the processing and use, and can withstand various mechanical stresses in the SMT process. |

|

|

| |

|

|

|

|

| |

|

4-1. Taconic TLX-9 PCB |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4-2. TLX-9 Datasheet |

|

|

| |

|

Property |

Test Method |

Value |

Units |

Dielectric Constant @ 10 GHz |

IPC-TM 650 2.5.5.5 |

2.5 |

|

Dissipation Factor @ 10 GHz |

IPC-TM 650 2.5.5.5 |

0.0019 |

|

Moisture Absorption |

IPC-TM 650 2.6.2.1 |

<0.02 |

% |

Volume Resistivity |

IPC-TM 650 2.5.17.1 |

10^7 |

Mohm/cm |

Surface Resistivity |

IPC-TM 650 2.5.17.1 |

10^7 |

Mohm/cm |

Peel Strength (1oz copper) |

IPC-TM 650 2.4.8 |

12 |

N/mm |

Thermal Conductivity |

ASTM F 433 |

0.19 |

W/m/K |

x-y CTE |

ASTM D 3386 (TMA) |

9-12 |

ppm/°C |

z CTE |

ASTM D 3386 (TMA) |

130- 145 |

ppm/°C |

UL-94 Flammability Rating |

UL-94 |

V-0 |

|

|

|

|

| |

|

|

|

|

| |

|

5. Applications |

|

|

| |

|

TLX-9 provides reliable performance across a broad spectrum of RF applications.

- LNAs, LNBs, and LNCs

- PCS/PCN Large Format Antennas

- High Power Amplifiers

- Passive Components

|

|

|

| |

|

|

|

|

| |

|

6. Concluding Remarks |

|

|

| |

|

As a saying goes, “In high-frequency applications, SMT is not just a manufacturing process, but an engine of technological innovation.” SMT provides designers with more innovative space, allowing high-frequency PCBs to achieve dual improvements in performance and efficiency. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|