| |

|

| |

|

|

|

|

|

| |

|

What is Pad in High Frequency PCB? |

|

|

|

| |

|

1. Pad Definition and Function |

|

|

|

| |

|

Pads are metal areas on the surface of a PCB used for soldering the pins or leads of electronic components. They are crucial for establishing both electrical and mechanical connections between components and the circuit board. For example, when soldering a surface-mounted component (SMT) like a chip resistor to the PCB, the resistor's leads are soldered to the corresponding pads on the PCB, integrating the resistor into the circuit. |

|

|

| |

|

|

|

|

| |

|

2. Pad Shape and Size |

|

|

| |

|

Pads come in various shapes, commonly circular, square, or oval. Their sizes are determined by factors such as the dimensions of the component leads to be soldered, soldering process requirements, and current-carrying capacity. For instance, pads for high-current power pins are usually designed larger to ensure a good electrical connection and sufficient current capacity. Typically, the diameter of pads for small power surface-mounted components might range from 0.3 to 0.5 mm, while those for high-power components can reach 1 to 2 mm or even larger. |

|

|

| |

|

|

|

|

| |

|

3. Pad Classification |

|

|

| |

|

3.1 Through-Hole Pads

These are used for inserted components and feature a hole through which the component leads pass, allowing for soldering on both sides of the PCB. For example, traditional through-hole resistors, capacitors, and integrated circuits use through-hole pads.

3.2 Surface-Mount Pads

These are designed for surface-mounted components and do not have holes passing through the PCB. The pads for surface mount technology (SMT) make direct contact with the leads or metal areas on the bottom of the package of the components, and most small surface-mounted components on mobile phone circuit boards are soldered using surface-mount pads.

|

|

|

| |

|

|

|

|

| |

|

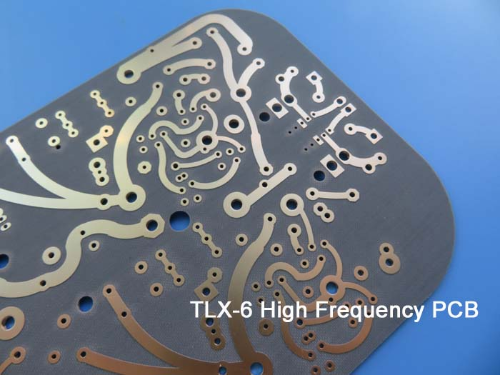

4. An Overview of Taconic TLX - 6 PCB |

|

|

| |

|

Speaking of pad , it reminds me of the Taconic TLX series of high - frequency PCBs. TLX is a dependable workhorse in the RF microwave substrate industry, where fiberglass delivers mechanical reinforcement in regions that faces harsh environments.Next, let's introduce the Taconic TLX - 6 laminate in detail. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.1 Advantages of Taconic TLX-6 substrate in Pad Design |

|

|

| |

|

Advantage Aspect |

Specific Content |

Example of Data Support |

Electrical Performance |

The dielectric constant is 2.65+/-0.04, reducing signal transmission delay. |

Compared with materials with a dielectric constant of 3.0, the signal propagation speed can be increased by approximately 10.5%. |

Electrical Performance |

Low dielectric loss, with a dissipation factor as low as 0.0022 at 10 GHz. |

Reduces signal attenuation and improves signal transmission integrity. |

Electrical Performance |

High insulation performance, with high volume resistivity and surface resistivity. |

The volume resistivity can reach over 10^7 ohm - cm. |

Physical Properties |

Strong copper foil adhesion, with a high peel strength for 1 - ounce copper foil. |

Can reach 10 lbs/linear inch to prevent copper foil from peeling off. |

Physical Properties |

Good dimensional stability and low coefficient of thermal expansion. |

In the temperature range from - 40°C to + 85°C, the coefficient of thermal expansion is around 10 ppm/°C. |

Physical Properties |

Offers a variety of thickness options and high surface flatness. |

The flatness error can be controlled within ±0.001 inches. |

Environmental Adaptability |

Good moisture resistance and low moisture absorption rate. |

In an environment with 90% relative humidity, the moisture absorption rate can be controlled below 0.1%. |

Environmental Adaptability |

Excellent chemical resistance. |

The performance is not significantly affected when in contact with common organic solvents and weak acid - base solutions. |

|

|

|

| |

|

|

|

|

| |

|

From the table above, it can be seen that Taconic TLX-6 substrate in pad design excels in electrical performance, leveraging low dielectric constant, low loss, and high insulation resistance to enhance signal transmission speed and integrity. Meanwhile, its strong copper foil adhesion, stable dimensional properties, and excellent moisture/chemical resistance ensure robust physical structure and adaptability to complex environments. |

|

|

| |

|

|

|

|

| |

|

4.2 Applications of Taconic TLX-6 Laminate |

|

|

| |

|

• Antennas

• Mixers, Splitters, Filters &Combiners

• Passive Components |

|

|

| |

|

|

|

|

| |

|

5. Final Insights |

|

|

| |

|

In high-frequency PCB design, the precise layout and size of pads directly impact signal integrity and electrical performance. Optimizing pad structures can effectively reduce parasitic inductance and capacitance, ensuring that signals remain stable and clear during high-speed transmission. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|