| |

|

| |

|

|

|

|

|

| |

|

What is PCB Rivet in High Frequency PCB? |

|

|

|

| |

|

1. Structure and material of PCB Rivet |

|

|

|

| |

|

A PCB rivet is a kind of fastening component used in printed circuit boards (PCBs). It is usually made of metal materials such as copper, aluminum, or stainless steel. It consists of a cylindrical shaft and a head. The shaft has a certain length and diameter, and the head is used to fix the rivet in place and provide a bearing surface. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

2. Function and application of PCB Rivet |

|

|

| |

|

PCB rivets are mainly used to fix various components on the PCB, such as connectors, transformers, and capacitors. They can also be used to connect different layers of the PCB or to fix the PCB to other components or equipment. By riveting, the components can be firmly fixed on the PCB, ensuring good electrical contact and mechanical stability, and improving the reliability and stability of the entire circuit. |

|

|

| |

|

|

|

|

| |

|

3.Tools for PCB Rivet Installation |

|

|

| |

|

3.1 Rivet Guns

Manual: Hand - used, great for small - scale DIY/workshop. Cheap, easy, comes in sizes for different rivet diameters.

Pneumatic: Air - powered, more powerful, better for factory mass - production.

3.2 Riveting Presses

Mechanical: Uses mechanical force (lever/screw), gives stable high - pressure, suits high - strength riveting in aerospace/military PCBs.

Hydraulic: Hydraulic - fluid - driven, applies high pressure, offers precision for medical device PCBs.

3.3 Hole - making Tools

Hole punchers/drills make holes in PCB. Hole size must match rivet. Hand - held drills for small jobs, automated ones in manufacturing.

3.4 Tweezers and Pliers

Tweezers place small rivets accurately. Pliers hold PCB during riveting or remove broken mandrels. |

|

|

| |

|

|

|

|

| |

|

4.Compatibility of Wangling WL-CT330Z PCB with Rivets |

|

|

| |

|

When discussing the suitability of rivets in PCBs, WL-CT330Z high-frequency PCB immediately comes to my mind. Its advantages in terms of PCB Rivet applicability are as follows:

4.1 Peel Strength Ensures Connection Reliability

Under the condition of 1OZ RTF copper foil, the peel strength of WL-CT330Z laminate reaches 0.85N/mm. The high peel strength ensures a tight bond between the copper foil and the substrate. When installing rivets, the copper foil is not easily peeled off from the substrate due to mechanical external force (such as the pressure during riveting), guaranteeing the electrical performance and physical stability of the rivet connection area.

4.2 Thermal Expansion Adapts to Temperature Variations

Its thermal expansion coefficients are 15 ppm/℃ in the X-direction, 13 ppm/℃ in the Y-direction, and 39 ppm/℃ in the Z-direction. In scenarios with temperature changes, the substrate’s thermal expansion deformation is controllable, reducing the risk of cracking or loosening at the junction between the rivet and the PCB caused by thermal stress. This is especially suitable for equipment subject to temperature cycling (such as industrial control and communication devices).

4.3 Strong Thermal Stress Tolerance

During the thermal stress test at 288℃, 10s, 3 times, WL-CT330Z shows no delamination. This means that even after multiple high-temperature impacts, the substrate structure remains stable, and the rivet installation area will not fail due to delamination caused by thermal stress, ensuring the reliability of rivet connections during long-term use.

4.4 Wide Temperature Range Expands Applications

The long-term operating temperature range is -55~+260℃, covering extremely cold to high-temperature environments. Whether it’s maintaining the mechanical properties of rivets in low-temperature environments or the compatibility between the substrate and rivets in high-temperature environments, WL-CT330Z can meet the requirements, making it suitable for fields with strict temperature variation requirements, such as aerospace and automotive electronics. |

|

|

| |

|

|

|

|

| |

|

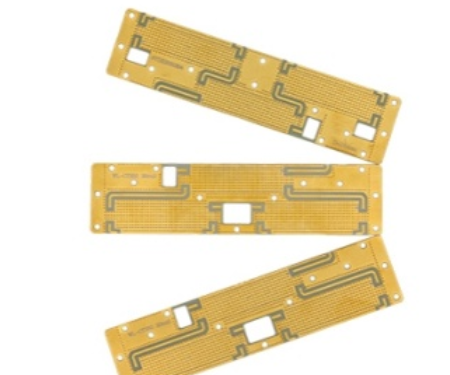

4-1. WL-CT Series PCB |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4-2. Our PCB Capability (WL-CT) |

|

|

| |

|

PCB Capability (WL-CT Series) |

PCB Material: |

Hydrocarbon resin, ceramic, and glass fiber cloth |

Designation (WL-CT Series) |

Designation |

DK |

DF |

WL-CT300 |

3.0±0.05 |

0.0030 |

WL-CT330 |

3.3±0.06 |

0.0026 |

WL-CT330Z |

3.3±0.06 |

0.0030 |

WL-CT338 |

3.38±0.05 |

0.0029 |

WL-CT350 |

3.48±0.05 |

0.0039 |

WL-CT440 |

4.1±0.08 |

0.0050 |

WL-CT615 |

6.15±0.15 |

0.0040 |

Layer count: |

Single Sided, Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Dielectric thickness |

ED Copper |

TRF Copper |

4mil |

/ |

8mil |

8.7mil |

12mil |

/ |

16mil |

/ |

20mil |

20.7mil |

28mil |

/ |

32mil |

32.7mil |

40mil |

40.7mil |

60mil |

60.7mil |

80mil |

80.7mil |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc.. |

|

|

|

| |

|

|

|

|

| |

|

5.End Note |

|

|

| |

|

As a core component of high-frequency PCBs, PCB Rivet, with its exceptional performance and stability, ensures the precise transmission of high-frequency signals, driving technological breakthroughs and leading the trends of the future. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|