| |

|

| |

|

|

|

|

|

| |

|

What is Impedance Control in High-Frequency PCB ? |

|

|

|

| |

|

1.The Introduction of Impedance Control |

|

|

|

| |

|

In high-frequency PCBs, impedance control refers to keeping the impedance of the high-frequency signal transmission lines on the circuit board stable (which is similar to the resistance of current transmission). Through design and material selection, the signal quality can be ensured and the equipment can work properly. By attaining precise impedance matching, designers of high-frequency PCBs can efficiently eliminate signal reflections and boost the performance of the circuit. This process is crucial because even the slightest impedance mismatch can cause signal distortion and impact the overall functionality of the device. |

|

|

| |

|

|

|

|

| |

|

2. The Impact of Different Dielectric Materials on Impedance Control |

|

|

| |

|

The influence of different dielectric materials on impedance control can be summarized in three key aspects:

2.1 Dielectric Constant:

Directly affects characteristic impedance; the higher the dielectric constant of the material, the lower the impedance value, and vice versa.

2.2 Loss Factor:

Determines the energy loss of the signal during transmission; low-loss materials can improve signal integrity.

2.3 Temperature Stability:

The temperature stability and thickness of the material can also affect the consistency of impedance, ensuring stability under various operating conditions. |

|

|

| |

|

|

|

|

| |

|

3. Practical Application Examples |

|

|

| |

|

In practical applications, different dielectric materials exhibit their own advantages.

For example: FR-4 materials are suitable for general electronic devices but may lead to signal loss in high-frequency applications. Rogers RO4000 series and RT/Duroid 6002 materials are widely used in RF and microwave circuits due to their low dielectric constant and loss factor, ensuring excellent impedance control. Next, let's further look into the outstanding product in the Rogers RO4000 series, the Rogers RO4360G2 PCB. |

|

|

| |

|

|

|

|

| |

|

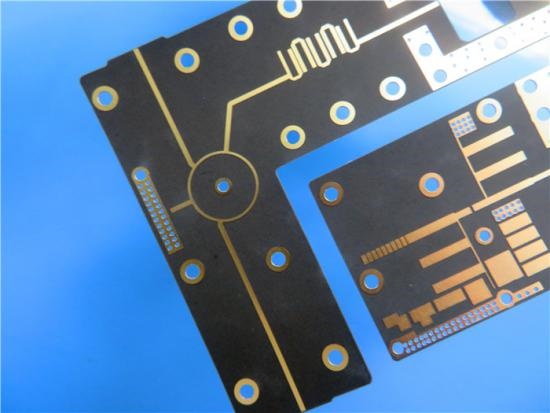

4. Description of Rogers RO4360G2 |

|

|

| |

|

Rogers RO4360G2 high-frequency PCBs possess numerous remarkable features and advantages, which are detailed as follows: |

|

|

| |

|

|

|

|

| |

|

4.1 Specially Formulated Thermosetting Resin System |

|

|

| |

|

Its dielectric constant is 6.15 ± 0.15, which is highly suitable for high-frequency applications and can effectively reduce signal delay.

The processing is as easy as that of FR-4, ensuring design flexibility.

It has high reproducibility, guaranteeing production consistency.

With low loss( DF of 0.0038), it reduces energy loss and maintains signal strength.

It offers a lower cost compared to competing PTFE products.

It has high thermal conductivity (0.75W/mK at50℃), making it suitable for high-power applications and ensuring excellent thermal stability. |

|

|

| |

|

|

|

|

| |

|

4.2 Low Z-Axis CTE / High Tg |

|

|

| |

|

Its Z-Axis CTE is 28 ppm/℃(-50℃to 288℃) and Tg is higher than 280 degrees centigrade TMA. It can support complex PCB designs, providing designers with more possibilities.

The plated through-holes have high reliability, improving the quality of the product during the manufacturing process.

It is compatible with automated assembly, meeting the requirements of modern production lines. |

|

|

| |

|

|

|

|

| |

|

4.3 Environmentally Friendly |

|

|

| |

|

Rogers RO4360G2 is lead-free compatible, conforming to environmental regulations and being suitable for green manufacturing. |

|

|

| |

|

|

|

|

| |

|

4.4 Regional Finished Goods Inventory |

|

|

| |

|

RO4360G2 PCB has short lead times and quick inventory turnover, enabling it to meet market demands in a timely manner. The efficient supply chain optimizes the production and distribution processes and enhances customer satisfaction. |

|

|

| |

|

|

|

|

| |

|

4-1. Description of Rogers RO4360G2 |

|

|

| |

|

Features and Advantages |

Details |

Specially Formulated Thermosetting Resin System |

- Dielectric constant: 6.15 ±0.15 for high-frequency, reduces signal delay.

- Easy processing like FR-4.

- High reproducibility.

- Low loss.

- Lower cost than PTFE.

- High thermal conductivity for high-power and stability.

|

Low Z-Axis CTE / High Tg |

Supports complex designs.

Reliable plated through-holes.

Compatible with automated assembly. |

Environmentally Friendly |

Lead-free compatible. |

Regional Finished Goods Inventory |

Short lead times.

Efficient supply chain. |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

5.Typical Applications |

|

|

| |

|

Base Station Power Amplifiers

Small Cell Transceivers

Patch Antennas

Ground-based Radar |

|

|

| |

|

|

|

|

| |

|

5-1. RO4360G2 PCB Specification |

|

|

| |

|

Category |

Details |

Standard Thickness |

0.008” (0.203mm), 0.012” (0.305mm), 0.016”(0.406mm), 0.020” (0.508mm), 0.024” (0.610mm), 0.032” (0.813mm), 0.060” (1.524mm) |

Standard Panel Size |

12” X 18” (305 X457 mm), 24” X 18” (610 X 457 mm), 48” X 36” (1.224 m X 915 mm) |

Standard Copper Cladding |

½ oz. (18μm), 1 oz. (35μm), 2 oz. (70μm) electrodeposited copper foil |

PCB size |

≤400mm X 500mm |

|

|

|

| |

|

|

|

|

| |

|

6. Final Thoughts |

|

|

| |

|

As the demand for high-frequency signal transmission in electronic devices keeps increasing, gaining an in-depth understanding and application of impedance control will become the key to improving the design level of high-frequency PCBs. The wonderfulness of high-frequency PCBs is inseparable from the elaborate craftsmanship in impedance control. Let's jointly create an electronic legend. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with exceptional service. Feel free to consult and contant at any time ! |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|