| |

|

| |

|

|

|

|

|

| |

|

What is Electrical Strength in High Frequency PCB? |

|

|

|

| |

|

1. Meaning of Electrical Strength |

|

|

|

| |

|

In high-frequency PCB design, electrical strength is one of the crucial factors to ensure signal integrity and device reliability. Electrical strength refers to the ability of a material to resist electrical breakdown under specific conditions, directly affecting the performance and safety of the circuit. |

|

|

| |

|

|

|

|

| |

|

2. Significance of Electrical Strength |

|

|

| |

|

Electrical strength is vital in circuit systems and closely linked to the failure rate. Under high-frequency conditions, it directly impacts the circuit failure risk, and improving it can reduce the risk and ensure stable circuit operation. For high-frequency applications, its significance is more prominent as it affects signal clarity and is a decisive factor for system stability. |

|

|

| |

|

|

|

|

| |

|

3. Factors and Solutions for Electrical Strength |

|

|

| |

|

Several factors can affect the electrical strength of a PCB. The following table shows the main factors and their corresponding solutions. |

|

|

| |

|

Aspect |

Factor |

Solution |

Material Selection |

The insulation and dielectric properties of the material directly influence the electrical strength of the PCB. |

Select materials with high dielectric strength, such as PTFE or high-performance epoxy resin. |

Design Layout |

An unreasonable design layout can lead to the concentration of the electric field and increase the risk of breakdown. |

Optimize the wiring layout to avoid sharp corners and ensure uniform traces. |

Thermal Management |

Overheating can cause the performance of the material to decline, thus affecting the electrical strength. |

Implement a thermal management strategy, such as using heat sinks, fans, or thermal conductive materials. |

Environmental Factors |

Humidity, pollution, and chemicals can reduce the insulation performance of the material. |

Use materials with good environmental adaptability and take protective measures, such as coating or sealing. |

Production Process |

Improper production processes can lead to material defects and affect the electrical strength. |

Ensure strict control of the production process and conduct quality inspections. |

|

|

|

| |

|

|

|

|

| |

|

4. Main Features of Taconic TLY-5Z PCB |

|

|

| |

|

When it comes to the electrical strength of PCBs, I invariably think of Taconic TLY-5Z high-frequency PCB. TLY-5Z laminates are advanced, glass-filled, PTFE composites with woven fiberglass reinforcement,which makes it have many obvious advantages in terms of Electrical Strength. The following is the specific explanation. |

|

|

| |

|

|

|

|

| |

|

4.1 Low Dielectric Constant and Low Loss Tangent |

|

|

| |

|

Stable Dielectric Constant: At 1.9 GHz, the dielectric constant (DK) of TLY-5Z PCB is 2.2 ± 0.04, which can ensure excellent signal integrity in high-frequency applications.

Low Loss Tangent: At 10 GHz and 23 °C, the loss tangent (DF) of TLY-5Z laminate is 0.0015. It can minimize signal loss. In the millimeter-wave frequency band, the overall insertion loss of the circuit is lower, effectively maintaining the strength and quality of signal transmission. |

|

|

| |

|

|

|

|

| |

|

4.2 Good Temperature Stability |

|

|

| |

|

TLY-5Z laminate has a TCDK of -72 ppm/°C from -55 °C to 150 °C. Ensures stable electrical performance and consistent/reliable signal transmission in a wide temperature range, even in harsh environments. |

|

|

| |

|

|

|

|

| |

|

4.3 Strong Stability of Metallized Vias |

|

|

| |

|

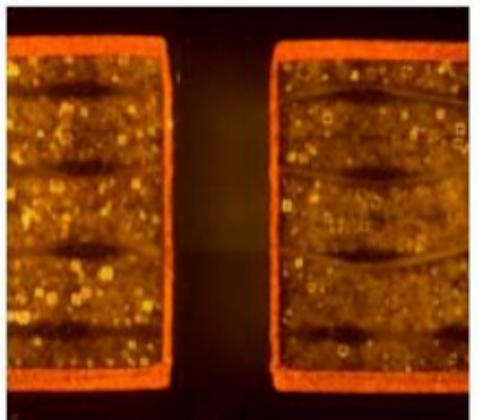

TLY-5Z substrate overcomes Z-axis expansion drawback of conventional low-DK PTFE materials. At 40 mils thickness and after 100 PTH thermal/cold cycles, no via hole fractures, improving long-term reliability. |

|

|

| |

|

|

|

|

| |

|

4-1. PTH Example of TLY-5Z after Thermal Cycle |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.4 Good Bonding Performance with Copper Foil |

|

|

| |

|

TLY-5Z PCB has excellent peel strength and good compatibility with planar copper foil. Tightly bonds with copper foil for effective signal transmission and avoids issues caused by poor bonding. |

|

|

| |

|

|

|

|

| |

|

4.5 High Design Flexibility |

|

|

| |

|

Low dielectric constant of TLY-5Z substrate allows for wider RF line design under the same dielectric thickness and impedance control, providing greater flexibility for high-frequency circuit design and facilitating circuit layout optimization and signal transmission efficiency improvement. |

|

|

| |

|

|

|

|

| |

|

5. Applications of Taconic TLY-5Z PCB |

|

|

| |

|

Aerospace Components

Low Weight Antennas for Aircraft

RF Passive Components |

|

|

| |

|

|

|

|

| |

|

6. End Note |

|

|

| |

|

"Enhancing electrical strength means better product quality." In high-frequency, it's decisive for signal. As electronic devices are developing towards smaller size and higher frequency, understanding and enhancing electrical strength becomes particularly indispensable. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|