| |

|

| |

|

|

|

|

|

| |

|

What is ED Copper in High Frequency PCB? |

|

|

|

| |

|

1. Electrodeposition Principle |

|

|

|

| |

|

Standard electrodeposited (ED) copper foil manufacturing relies on electrolysis. A DC - connected titanium rotating drum acts as the cathode, with the anode in a copper - ion - filled electrolyte. When an electric field is applied, copper ions move to the cathode, gain electrons, and deposit as copper (Cu²? + 2e? → Cu), enabling uniform deposition. |

|

|

| |

|

|

|

|

| |

|

2. Deposition Process and Parameter Influence |

|

|

| |

|

2.1 Rotating Drum's Role:

The slow - rotating titanium drum's speed determines copper foil thickness. Slower speed means more deposition time and a thicker foil; faster speed leads to a thinner one, allowing for precise thickness production.

2.2 Deposition Surface Features:

The drum - contact side of the deposited copper is smooth from even deposition, while the other side is rough due to solution flow and ion distribution affecting the deposition structure. |

|

|

| |

|

|

|

|

| |

|

3. Surface Treatment Process |

|

|

| |

|

3.1Treatment Cycles:

After peeling from the drum, the rough side of the copper foil is roughened to boost adhesion in PCB manufacturing, and the smooth side is flattened and cleaned for quality.

3.2Treatment Significance:

In PCB manufacturing, the treatment strengthens the bond between copper and the dielectric interlayer during lamination, and also functions as an anti - oxidation agent, prolonging the copper foil's lifespan and ensuring PCB reliability. |

|

|

| |

|

|

|

|

| |

|

4. Rogers TC600 Laminate in ED Copper |

|

|

| |

|

Speaking of the application of board tooling holes, Rogers TC600 high-frequency PCB springs to my mind.

Meet the TC600 PCB, a high-performance printed circuit board substrate poised to transform the electronics landscape. Crafted with woven fiberglass reinforcement, ceramic fillers, and a PTFE-based composite, this innovative PCB delivers outstanding heat transfer capabilities, minimized dielectric and insertion losses, and enhanced mechanical durability. Experience the difference with the TC600 and elevate your electronic designs to new heights!

The following characteristics and advantages can be highlighted for the Rogers TC600 in relation to electrodeposited (ED) copper:

4.1Low Surface Roughness:

As indicated by the data, the top surface roughness of Rogers TC600™ is consistently 0.4 μm for copper foil weights or thicknesses of 2 oz (70 μm), 1 oz (35 μm), and ½ oz (18 μm). The dielectric side surface roughness measures 1.6 μm, 1.5 μm, and 1.6 μm respectively. The low surface roughness on the top effectively reduces signal scattering and loss during high-frequency signal transmission. Compared to rougher copper foils, this enhances signal integrity, improving the signal quality in communication devices and other products.

4.2Consistent Roughness Performance:

The top surface roughness of Rogers TC600™ remains stable at 0.4 μm across different copper foil thicknesses, demonstrating its production process stability. This consistency allows for reduced adjustments in manufacturing parameters when copper foil thickness varies, simplifying production complexity and lowering costs while ensuring consistent performance across different product specifications. |

|

|

| |

|

|

|

|

| |

|

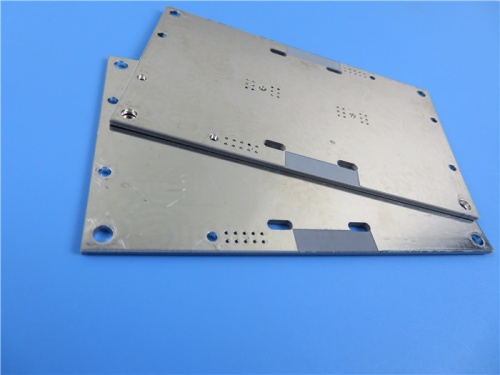

4-1 Double Layer 30mil RogersTC600 PCB |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4-2. Additional PCB construction details |

|

|

| |

|

Construction Details |

Specifications |

Board dimensions |

61.99mm x 39.99mm (+/- 0.15mm) |

Minimum Trace/Space |

5/5 mils |

Minimum Hole Size |

0.3mm |

Blind vias |

No |

Finished board thickness |

0.8mm |

Finished Cu weight |

1oz (1.4 mils) |

Via plating thickness |

20 μm |

Surface finish |

Immesion Gold |

|

|

|

| |

|

|

|

|

| |

|

5. Wrap-Up |

|

|

| |

|

For high - frequency PCBs, electrodeposited (ED) copper is the "golden link" for efficient signal conduction. With its outstanding electrical properties, it enables high - frequency signals to be transmitted precisely, just like lively musical notes. Moreover, it is the "iron backbone" that fears no environmental challenges. Thanks to its excellent physical characteristics, it supports high - frequency PCBs to operate continuously and reliably under complex working conditions. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|