| |

|

| |

|

|

|

|

|

| |

|

What is Dimensional Stability in High Frequency PCB ? |

|

|

|

| |

|

1. Understanding Dimensional Stability |

|

|

|

| |

|

Dimensional stability refers to the ability of a high frequency Printed Circuit Board (PCB) to maintain its original shape, size, and mechanical properties under various environmental conditions such as temperature changes, humidity fluctuations, and mechanical stress. It is a crucial characteristic that directly impacts the performance and reliability of the PCB. |

|

|

| |

|

|

|

|

| |

|

2.The Significance of Dimensional Stability |

|

|

| |

|

2.1 Unraveling the Precision Secrets for PCB Excellence

Dimensional stability in high frequency PCBs ensures that the board maintains its precise shape and size. This is crucial as even the slightest deviation can impact the performance. Precision in every dimension is not just a goal; it's the essence of our PCB's dimensional stability, ensuring your projects stand the test of time and technology.

2.2 Ensuring Dimensional Stability for PCB Performance

One of the critical aspects is material selection. A well-controlled manufacturing process is equally essential. By carefully monitoring and controlling each step, we can achieve the desired level of dimensional stability. This, in turn, leads to improved reliability and performance of the high frequency PCB, making it suitable for a wide range of applications. |

|

|

| |

|

|

|

|

| |

|

3. Methods for Improving Dimensional Stability |

|

|

| |

|

3.1 Material Selection

Choose substrate materials with low thermal expansion coefficients, which can effectively reduce dimensional deformation caused by temperature changes.

Consider material compatibility. Ensure copper foil and prepreg have thermal expansion coefficients matching the substrate material to avoid internal stress from thermal expansion differences and maintain dimensional stability.

3.2 Design Optimization

Plan component and trace layout rationally, preventing stress concentration and considering compensation structures.

3.3 Process Control

Strictly control parameters in lamination, drilling, and etching to minimize deformations.

3.4 Quality Inspection

Use precise tools to monitor PCB dimensions and feed data back for process adjustments. |

|

|

| |

|

|

|

|

| |

|

4. Superiorities of RF-35TC PCB in Dimensional Stability |

|

|

| |

|

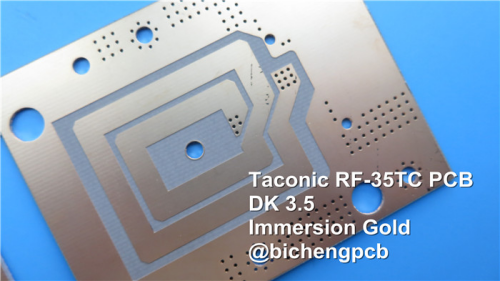

Speaking of the dimensional stability of PCBs, Taconic RF-35TC high-frequency PCB springs to my mind. Let's delve into the key details and superiorities of this remarkable product. |

|

|

| |

|

|

|

|

| |

|

4.1 Fiberglass-Reinforced Design |

|

|

| |

|

Taconic RF - 35TC PCB is a PTFE - based, ceramic - filled fiberglass substrate with balanced mechanical properties and excellent dimensional stability. |

|

|

| |

|

|

|

|

| |

|

4-1. Taconic RF - 35TC PCB |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.2 Low Water Absorption |

|

|

| |

|

Extremely low water absorption rate of 0.05%, minimizing dimensional impact in humid environments. |

|

|

| |

|

|

|

|

| |

|

4.3 High Glass Transition Temperature |

|

|

| |

|

Tg > 315℃ ensures dimensional stability under high temperatures, preventing deformation during processing and use. |

|

|

| |

|

|

|

|

| |

|

4.4 Low Coefficient of Thermal Expansion (CTE) |

|

|

| |

|

- x-axis: 11 ppm/℃

- y-axis: 13 ppm/℃

- z-axis: 34 ppm/℃

Low CTE across all axes ensures strong dimensional stability. |

|

|

| |

|

|

|

|

| |

|

4.5 Dielectric Constant Stability |

|

|

| |

|

- Low Dielectric constant (Dk): 3.50

- Low Dissipation factor (Df): 0.0011

- Stable TCDK: 24 ppm ( -30℃ to 120℃)

RF-35TC laminate has a relatively stable internal structure and properties, with minimal dimensional changes at different temperatures, providing a stable dielectric environment for high-frequency signal transmission |

|

|

| |

|

|

|

|

| |

|

4.6 Dimensional Changes |

|

|

| |

|

Condition |

MD Direction (mils/in) |

CD Direction (mils/in) |

After etching |

0.23 |

0.64 |

Under thermal stress |

-0.04 |

0.46 |

|

|

|

| |

|

|

|

|

| |

|

The dimensional changes of RF-35TC substrate under etching and thermal stress are extremely small, ensuring excellent dimensional precision as the impact of external factors is negligible.

Based on the above data and comprehensive analysis, we can conclude that RF-35TC PCB has excellent dimensional stability due to its low water absorption, high-temperature stability, excellent dimensional precision, stable dielectric properties, and fiberglass-reinforced design that balances mechanical properties and resists environmental effects, making it ideal for high power applications. |

|

|

| |

|

|

|

|

| |

|

6. Summary |

|

|

| |

|

Dimensional stability is paramount for high-frequency PCBs, as it directly impacts performance and reliability. As the saying goes, "Precision is the linchpin of PCB stability." To achieve optimal performance and application, it's essential to select appropriate materials, refine designs, manage production processes, and conduct thorough inspections and feedback. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|