| |

|

| |

|

|

|

|

|

| |

|

What is Density in High Frequency PCB? |

|

|

|

| |

|

1.The Overview of the coefficient of thermal expansion |

|

|

|

| |

|

In the realm of high-frequency printed circuit boards , "density" usually refers to the mass density of materials, that is, the mass per cubic meter (in grams), which is used to measure the physical properties of substrates (such as FR-4, PTFE, etc.) and has a significant impact on signal transmission performance and overall performance. |

|

|

| |

|

|

|

|

| |

|

2. The Impact of Density in High-Frequency PCBs |

|

|

| |

|

2.1 Signal Integrity

The material density is related to the dielectric constant and loss factor, affecting the signal propagation speed and attenuation.

2.2 Heat Dissipation Performance

Higher density usually means better thermal conductivity, which is crucial for heat dissipation in high-power applications.

2.3 Mechanical Strength

Materials with higher density usually have better mechanical strength and durability, suitable for demanding application environments. |

|

|

| |

|

|

|

|

| |

|

3. Selecting the Appropriate Material Mass Density |

|

|

| |

|

3.1 Signal Transmission Aspect

Ensure that the material mass density can provide an appropriate dielectric constant to reduce signal reflection and attenuation, and at the same time, a low loss factor ensures efficient signal transmission.

3.2 Heat Dissipation Requirements

Understand the relationship between thermal conductivity and mass density. Materials with higher mass density may have high thermal conductivity and need to cooperate well with the heat dissipation structure.

3.3 Mechanical Properties

Select according to the application environment. If it is necessary to withstand mechanical stress, materials with high mass density and good strength can be considered, while paying attention to the impact on weight.

3.4 Cost Factors

Include material costs and processing costs, and balance performance and cost to choose materials with appropriate mass density. |

|

|

| |

|

|

|

|

| |

|

4. Introduction to the Rogers 4000 Series |

|

|

| |

|

The Rogers 4000 series consists of multiple materials such as RO4006 and RO4003C substrates. The RO4000® hydrocarbon ceramic laminate materials not only have high mass density but also possess excellent high-frequency performance, such as low dielectric constant and loss tangent, strong flexural strength and high temperature tolerance.

The RO4003C PCB has a mass density of 1.8g/cm³ at 23°C, and the Electrodeposited Copper Foil: ½ oz. (18μm) HH/HH or 1 oz. (35μm) H1/H1. The following is a specific introduction to RO4003C datasheet. |

|

|

| |

|

|

|

|

| |

|

4-1. RO4003C PCB Specifications |

|

|

| |

|

Property |

Typical Value |

Direction |

Units |

Condition |

Dielectric Constant, ε<sub>r</sub> Process |

3.38 ± 0.05 |

Z |

- |

10 GHz/23°C |

Dielectric Constant, ε<sub>r</sub> Design |

3.55 |

Z |

- |

8 to 40 GHz |

Dissipation Factor tan, d |

0.0021 |

Z |

- |

10 GHz/23°C |

Thermal Coefficient of,e |

+40 |

Z |

ppm/°C |

-50°C to 150°C |

Flexural Strength |

276 (40) |

- |

MPa (kpsi) |

- |

Dimensional Stability |

<0.3 |

X, Y |

mm/m (mils/inch) |

after etch +E2/150°C |

Coefficient of Thermal Expansion |

11

14

46 |

X

Y

Z |

ppm/°C |

-55 to 288°C |

Thermal Conductivity |

0.71 |

- |

W/m/°K |

80°C |

|

|

|

| |

|

|

|

|

| |

|

4.1. Some Typical Applications of the Rogers 4000 Series: |

|

|

| |

|

• Cellular Base Station Antennas and Power Amplifiers

• RF Identification Tags

• Automotive Radar and Sensors

• LNB’s for Direct Broadcast Satellites |

|

|

| |

|

|

|

|

| |

|

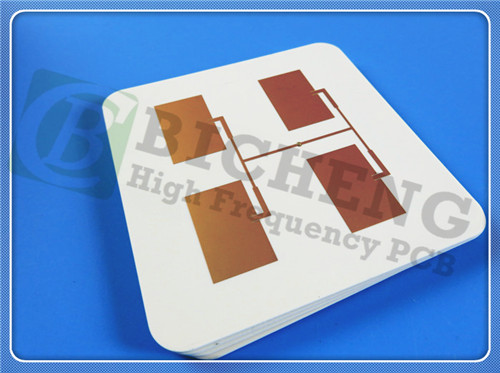

4-2. RO4003C Multilayer PCB 4-Layer 4.8mm Thick

|

|

|

| |

|

|

|

|

| |

|

5. Methods for Optimizing Material Mass Density |

|

|

| |

|

5.1 Material Selection

• Substrate Materials: Compare PTFE materials with different ceramic filling ratios, or use alternative materials with slightly lower mass density to balance performance and cost.

• Copper Foil Selection: Select electrolytic copper foil or rolled copper foil according to requirements, considering the relationship among mass density, electrical conductivity and cost.

5.2 Design Layout

• Reasonable Wiring Density: Avoid overly dense wiring. Adopt the design of multi-layer boards and arrange the circuits in layers to reduce the overall mass density.

• Component Layout Optimization: Arrange the component layout reasonably, disperse the heat-generating components, improve electromagnetic compatibility and reduce the mass density of shielding materials.

5.3 Manufacturing Process

• Processing Precision Control: Improve the precision of processes such as etching and drilling to reduce material waste and control mass density.

• Material Molding Process: Adopt appropriate processes to make the filling materials distribute evenly and optimize the overall mass density. |

|

|

| |

|

|

|

|

| |

|

6. Concluding Remarks |

|

|

| |

|

Density in high-frequency PCBs is like the cornerstone that supports the edifice of performance. It not only affects signal integrity, heat dissipation performance and mechanical strength, but also serves as a key factor in balancing performance and cost during the design and manufacturing processes. Only by deeply understanding and optimizing density can high-frequency PCBs shine in the rapidly developing electronic world. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|