| |

|

| |

|

|

|

|

|

| |

|

What circuit boards do we do? (7)

RT/duroid 6010.2LM High frequency PCB

|

|

|

|

| |

|

Shot 1: brief introduction |

|

|

|

| |

|

Rogers RT/duroid 6010.2LM laminates are ceramic-PTFE composites specifically engineered for electronic and microwave circuits that demand a high dielectric constant. With its high dielectric constants (Dk), these laminates enable circuit size reduction, providing more compact and efficient designs. They are particularly well-suited for applications operating within X-band frequencies or lower due to their low loss properties. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Shot 2: Features |

|

|

| |

|

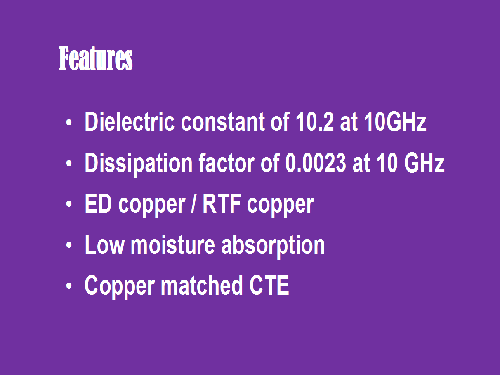

The RT/duroid 6010.2LM laminate offers several advantageous features:

Dielectric Constant (Dk): With a value of 10.2 and a tight tolerance of +/- 0.25, the laminate ensures precise Dk control, resulting in consistent and repeatable circuit performance.

Low Dissipation Factor: At just .0023 at 10 GHz, the laminate minimizes signal attenuation and distortion, facilitating reliable signal transmission.

Copper Foil Options: The Rogers 6010.2LM laminate offers flexible copper foil options, allowing you to choose between Electro-Deposited (ED) copper and Reverse-Treated Foil (RTF) copper. This flexibility enables catering to specific requirements in PCB manufacturing, including considerations such as insertion loss and PIM performance.

Moisture Absorption: The laminate exhibits low moisture absorption, enhancing its resistance to environmental conditions and preserving its electrical properties over time.

Coefficient of Thermal Expansion (CTE): The CTE values for the XYZ axes are 24, 24, and 47 ppm/°C, respectively. This supports the reliability of plated through-holes in multi-layer boards by ensuring secure and robust connections between layers, contributing to the overall reliability of the circuit. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Shot 3: PCB Capability |

|

|

| |

|

Now let’s delve into our capabilities on 6010.2 materials.

We can offer a variety of configurations to suit your needs, including Single Sided, Double Sided, Multi-layer, and Hybrid types to meet your specific design requirements.

Copper weight options include 1oz (35µm) and 2oz (70µm) and dielectric thickness includes 10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.90mm), and 100mil (2.54mm).

We can accommodate the sizes up to 400mm X 500mm, and solder mask colors such as Green, Black, Blue, Yellow, Red etc are available.

We also provide a diverse range of surface finish options, including Bare copper, HASL, ENIG, Immersion tin, Immersion Silver, OSP, Pure gold, and ENEPIG etc. |

|

|

| |

|

|

|

|

| |

|

PCB Capability (RT/duroid 6010.2LM) |

PCB Material: |

Ceramic-PTFE composite |

Designator: |

RT/duroid 6010.2LM |

Dielectric constant: |

10.2 ±0.25 (process); 10.7 (design) |

Layer count: |

Single Sided, Double Sided, Multi-layer, Hybrid Construction |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Dielectric thickness: |

10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.90mm), 100mil (2.54mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion tin, Immersion Silver, OSP, Pure gold, ENEPIG. |

|

|

|

| |

|

|

|

|

| |

|

Shot 4: PCB and Applications |

|

|

| |

|

The utilization of RT/duroid 6010.2LM PCBs extends to various cutting-edge applications, including Patch Antennas, Satellite Communications Systems, Power Amplifiers, Aircraft Collision Avoidance Systems, and Ground Radar Warning Systems etc.

Thank you. I’ll see you next time. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|