| |

|

| |

|

|

|

|

|

| |

|

What circuit boards do we do? (11)

TMM4 High Frequency PCB

|

|

|

|

| |

|

Shot 1: Introduction |

|

|

|

| |

|

Rogers TMM 4 is a thermoset microwave material designed to offer high plated-thru-hole reliability for strip-line and micro-strip applications. It is a composite material that combines the advantageous characteristics of ceramics, hydrocarbons, and thermoset polymers.

TMM 4 materials possess robust mechanical and chemical properties, providing many of the benefits found in both ceramic and traditional PTFE laminates. Unlike those materials, TMM 4 laminates do not require specialized production techniques. They are based on thermoset resins, ensuring reliable wire-bonding without the risk of pad lifting or substrate deformation. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Shot 2: Features |

|

|

| |

|

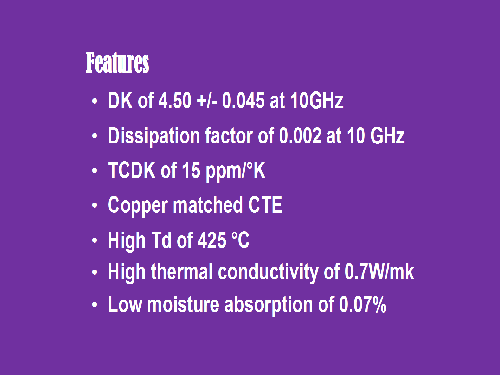

TMM4 laminates offer several key features as follows:

It has a dielectric constant of 4.50 +/- .045, providing stable electrical properties for high-frequency applications, and a dissipation factor of .0020 at 10GHz, indicating low signal loss and efficient signal transmission.

TMM4 has a thermal coefficient of Dk of 15ppm/°K, ensuring minimal changes in electrical performance with temperature variations.

The coefficient of thermal expansion is matched to copper, with values of x = 16 ppm/°K, y = 16 ppm/°K, and z = 21 ppm/°K. This compatibility reduces the risk of stress-related issues during thermal cycling.

TMM4 laminates have a high decomposition temperature (Td) of 425 °C TGA, ensuring their stability and reliability under elevated temperature conditions.

It exhibits a thermal conductivity of 0.7 W/mk, facilitating efficient heat dissipation in high-power applications.

TMM4 shows excellent resistance to moisture-related issues with moisture absorption rates of 0.07% for a thickness of 50mil and 0.18% for a thickness of 125mil. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Shot 3: PCB Capability |

|

|

| |

|

Our PCB manufacturing capability on TMM4 laminates is summarized in the following table.

We offer single sided, double sided, multi-layer and hybrid PCBs, providing flexibility to meet different design requirements.

We support copper weights of 1oz (35µm) and 2oz (70µm), allowing you to choose the appropriate copper weight for your specific application.

We provide a wide range of laminate thickness options to suit your needs, such as 15mil (0.381mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.270mm), 60mil (1.524mm), up to 500mil (12.7mm).

Our manufacturing capabilities support PCB sizes up to 400mm X 500mm, providing ample space for your designs.

We offer a variety of solder mask colors to suit your preferences and requirements, such as green, black, blue, yellow, red, and more.

Our surface finish options include bare copper, HASL, ENIG, immersion tin, immersion silver, pure gold (with no nickel under gold), OSP, and ENEPIG etc. |

|

|

| |

|

|

|

|

| |

|

PCB Capability (TMM4) |

PCB Material: |

Composite of Ceramic, hydrocarbon and thermoset polymer |

Designator: |

TMM4 |

Dielectric constant: |

4.5 ±0.045 (process); 4.7 (design) |

Layer count: |

Single Sided, Double Sided, Multi-layer, Hybrid designs |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Laminate thickness: |

15mil (0.381mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.270mm), 60mil (1.524mm), 75mil (1.905mm), 100mil (2.540mm), 125mil (3.175mm), 150mil (3.810mm), 200mil (5.08mm), 250mil (6.35mm), 500mil (12.7mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion tin, Immersion Silver, Pure gold (no nickle under gold), OSP, ENEPIG |

|

|

|

| |

|

|

|

|

| |

|

Shot 4: Applications |

|

|

| |

|

TMM4 High-Frequency PCBs are commonly used in various applications including power amplifiers and combiners, filters and couplers, satellite communication systems, Global Positioning Systems (GPS) antennas, patch antennas, and chip testers etc.

Thank you for watching. I'll see you next time. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|