|

|

|

|

|

|

|

Tg170 FR-4 and Polyimide Based 3 Layer Rigid-Flex PCB for Wireless Security Featuring Immersion Tin and Green Solder Mask |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General description |

|

|

Tg170 FR-4 and Polyimide PCB is a rigid-flex printed circuit board designed specifically for wireless security systems. Tg170 FR-4 PCB features a 3-layer construction with a rigid section thickness of 1.6mm. The board utilizes Shengyi base laminate and is manufactured in compliance with IPC 6012 Class 2 standards, based on provided Gerber data. |

|

|

|

|

|

Basic specifications |

|

|

Size of Flexible PCB |

91.5X 105.3mm |

Number of Layers |

3 |

Board Type |

Rigid-flex PCB |

Board Thickness |

1.6mm |

Board Material |

Polyimide (PI) 25µm +FR-4 |

Board Material Supplier |

Shengyi |

Tg Value of Board Material |

135℃ |

|

PTH Cu thickness |

≥20 µm |

Inner Iayer Cu thicknes |

35 µm |

Surface Cu thickness |

35 µm |

|

Coverlay Colour |

Yellow / Green Solder mask |

Number of Coverlay |

2 |

Thickness of Coverlay |

25 µm |

Stiffener Material |

NO |

Stiffener Thickness |

N/A |

|

Type of Silkscreen Ink |

IJR-4000 MW300 |

Supplier of Silkscreen |

TAIYO |

Color of Silkscreen |

White |

Number of Silkscreen |

1 |

|

Peeling test of Coverlay |

No peelable |

Legend Adhesion |

3M 90℃ No peeling after Min. 3 times test |

|

Surface Finish |

Immersion Tin |

Thickness of Surface Finish |

Tin: 0.8-1.5µm |

RoHS Required |

Yes |

Famability |

94-V0 |

|

Thermal Shock Test |

Pass, -25℃±125℃, 1000 cycles. |

Thermal Stress |

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

Function |

100% Pass electrical test |

Workmanship |

Compliance with IPC-A-600H & IPC-6013C Class 2 |

|

|

|

|

|

|

.JPG) |

|

|

|

|

|

Processes |

|

|

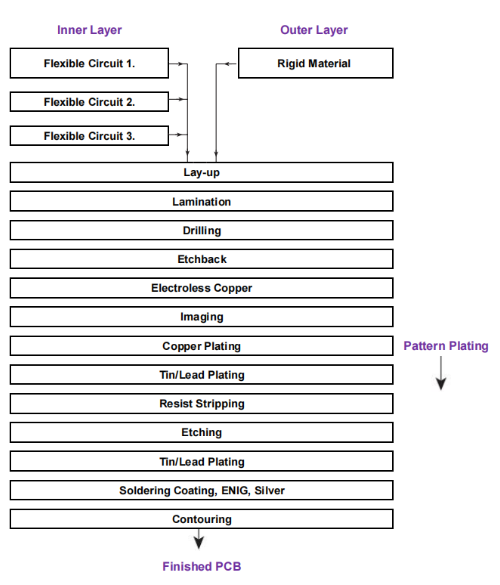

A simplified flow diagram is shown below. |

|

|

|

|

|

|

|

|

Features and benefits |

|

|

Excellent flexibility

Reducing the volume

Weight reduction

Increased reliability

The end can be whole soldered

Material optionality

Low cost

Continuity of processing

Professional and experienced engineers

Eligible products rate of first production: >95% |

|

|

|

|

|

Applications |

|

|

Laser head FPC, POS antenna soft board, tablet keypad flex board |

|

|

|

|

|

Multilayer Flexible Circuits and Rigid-Flex Circuits |

|

|

Both types of circuits are derived from traditional cover-coated double-sided flexible circuits that are laminated together. However, integrating an excessive number of flexible circuits into a multilayer flexible circuit is typically not recommended due to several technical and practical considerations. |

|

|

|

|

|

Materials and Thicknesses |

|

|

The following materials are typically employed: |

|

|

|

|

|

Dielectric Substrates |

|

|

A widely preferred option is 50 µm (2 mil) polyimide, as it offers improved stability and simpler handling compared to 25 µm (1 mil) polyimide. |

|

|

|

|

|

Copper Foil |

|

|

To meet the current-carrying requirements of the finished circuit, 35 µm (1 oz.) copper foil is frequently utilized, assuming this thickness satisfies the necessary specifications. |

|

|

|

|

|

Covercoat |

|

|

For effective conductor encapsulation, 25 µm (1 mil) polyimide is favored when paired with 35 µm (1.4 mil) thick copper foil, as opposed to 50 µm (2 mil) polyimide.

To ensure proper encapsulation and achieve a low-flow lamination process, 25 µm (1 mil) acrylic adhesive is typically used. However, excessive acrylic adhesive can result in reliability problems, such as barrel cracks, foil cracks, and excessive etchback depth. |

|

|

|

|

|

Outer Layers |

|

|

To minimize the risk of air entrapment at the interface, avoid placing circuitry (conductors) on the bonding side of the outer layers.

For multilayer flexible circuits, 50 µm (2 mil) polyimide is typically used for the outer layers, whereas rigid materials like glass epoxy FR-4 or glass fabric-reinforced polyimide are commonly employed in rigid-flex circuits.

In the case of thick rigid-flex circuits, polyimide composites (such as copper-clad polyimide films with adhesive on the bonding side) are sometimes utilized. Their increased overall thickness provides adequate rigidity to support components effectively. |

|

|

|

|

|

Bonding Materials |

|

|

Inner layers made of cover-coated flexible circuits are usually bonded to rigid sections using sheet adhesives. |

|

|

|

|

|

|

|

|

Hot Tags:

Tg170 FR-4 Immersion Tin PCB |

Tg170 FR-4 Green Solder Mask PCB |

3-Layer FR-4 PCB |

High Tg FR-4 PCB |

Tg170 FR-4 PCB |

|

|