| |

|

|

|

|

|

|

|

|

Taconic RF 60TC PCB 10mil 20mil 30mil and 60mil Laminate Coating with Immersion Gold/Tin/ HASL and OSP |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Taconic RF-60TC PCB is an advanced ceramic-filled PolyTetraFluoride (PTFE)-based fiberglass substrate engineered specifically for high-power RF and microwave printed circuit boards. Tailored for the 6.15DK market, it's designed to significantly lower operating temperatures in high-power scenarios by optimizing dielectric heat dissipation and achieving exceptionally low dielectric losses. This translates to enhanced gain and efficiency, especially in miniaturized antenna applications where space and performance are at a premium.

RF-60TC material's superior heat transfer capabilities provide additional design flexibility, allowing engineers to extend the lifespan of active components and improve long-term reliability.

Taconic RF-60TC PCB features extremely low-profile and reverse-treated copper, which effectively reduces insertion loss, while also offering heavy metal-based laminate options for applications requiring higher current-carrying capacity. With its low coefficient of thermal expansion (CTE) and improved dimensional stability, RF-60TC laminate enables the fabrication of multi-layer PCBs with enhanced plated-through-hole (PTH) reliability, making it a top choice for complex, high-performance RF and microwave systems such as high-power amplifiers, radar equipment, and satellite communications. |

|

|

.jpg) |

|

|

|

|

|

Our PCB Capability (RF-60TC) |

|

|

PCB Capability (RF-60TC) |

PCB Material: |

PTFE based, ceramic filled fiberglass |

Designation: |

RF-60TC |

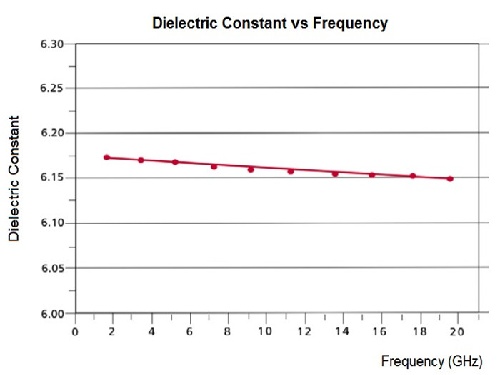

Dielectric constant: |

6.15± 0.15 @10 GHz |

Dissipation factor: |

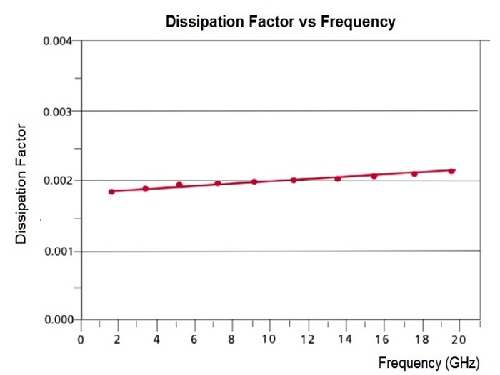

0.002 @10 GHz |

Layer count: |

Single Layer, Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

1oz (35 µm), 2oz (70µm) |

PCB thickness: |

5mil (0.127mm), 10mil (0.254mm); 20mil (0.508mm), 25mil(0.635mm); 30mil (0.762mm), 60mil (1.524mm) |

|

|

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, ENEPIG, OSP, Pure gold etc.. |

|

|

|

|

|

|

Benefits: |

|

|

1. Improved loss tangent

- Lower insertion loss

- Enhanced antenna gain / efficiency

2. High thermal conductivity

- Exceptional thermal management

- Lower operating temperature

- Higher power application

- Loong term reliablity

3. Enhanced dimensional stability

4. Low Z-axis CTE

- Multilayer application available

- Reliable plated through hole

5. Excellent adhesion to metal

- Lower profile copper available

- Heavy metal back available

6. Stable DK over frequency

7. Stable DK over temperature

8.Low moisture absorption |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Applications: |

|

|

High power amplifier

Miniaturized antennas (GPS / PATCH / RFID Reader)

Filters, couplers, dividers

Satellites |

|

|

|

|

Typical Value of RF-60TC |

|

RF-60TC Typical Values |

Property |

Test Method |

Unit |

Value |

Unit |

Value |

Dk @ 10 GHz |

IPC-650 2.5.5.5.1 (Modified) |

|

6.15 ± 0.15 |

|

6.15 ± 0.15 |

Df @ 10 GHz |

IPC-650 2.5.5.5.1 (Modified) |

|

0.002 |

|

0.002 |

TcK |

|

ppm/°C |

-3.581 |

ppm/°C |

-3.581 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

55 |

kV |

55 |

Dielectric Strength |

IPC-650 2.5.6.2 |

V/mil |

550 |

V/mm |

21,654 |

Arc Resistance |

IPC-650 2.5.1 |

Seconds |

>180 |

Seconds |

>180 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.03 |

% |

0.03 |

Flexural Strength (MD) |

IPC-650 2.4.4 |

psi |

10,000 |

N/mm2 |

69 |

Flexural Strength (CD) |

IPC-650 2.4.4 |

psi |

9,000 |

N/mm2 |

62 |

Tensile Strength (MD) |

IPC-650 2.4.19 |

psi |

9,000 |

N/mm2 |

62 |

Tensile Strength (CD) |

IPC-650 2.4.19 |

psi |

7,000 |

N/mm2 |

48 |

Young’s Modulus (MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

kpsi |

721 |

N/mm2 |

4971 |

Poisson’s Ratio (MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

|

0.155 |

|

0.155 |

Peel Strength (1 oz. ED) |

IPC-650 2.4.8 |

lbs/in |

8 |

N/mm |

1.43 |

Thermal Conductivity (Unclad) |

IPC-650 2.4.50 |

W/M*K |

0.9 |

W/M*K |

0.9 |

Thermal Conductivity (CH/CH) |

IPC-650 2.4.50 |

W/M*K |

1 |

W/M*K |

1 |

Thermal Conductivity (C1/C1) |

IPC-650 2.4.50 |

W/M*K |

1.05 |

W/M*K |

1.05 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.01 |

mm/M |

0.01 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.69 |

mm/M |

0.69 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) |

mils/in |

0.06 |

mm/M |

0.06 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) |

mils/in |

0.8 |

mm/M |

0.8 |

Surface Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm |

1.0 x 108 |

Mohm |

1.0 x 108 |

Volume Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm/cm |

1.0 x 108 |

Mohm/cm |

1.0 x 108 |

CTE (X, Y axis) |

IPC-650 2.4.41 (RT- 150 °C) |

ppm/°C |

9.9 |

ppm/°C |

9.9 |

CTE (Z axis) |

IPC-650 2.4.41 (RT- 150 °C) |

ppm/°C |

40 |

ppm/°C |

40 |

Density (Specific Gravity) |

IPC-650 2.3.5 |

g/cm3 |

2.84 |

g/cm3 |

2.84 |

Specific Heat |

IPC-650 2.4.50 |

J/gK |

0.94 |

J/gK |

0.94 |

Td (2% Wt. Loss) |

IPC - 650 2.4.24.6 / TGA |

°F |

930 |

°C |

500 |

Td (5% Wt. Loss) |

IPC - 650 2.4.24.6 / TGA |

°F |

960 |

°C |

515 |

Flammability Rating |

UL 94 |

|

V-0 |

|

V-0 |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

Double Sided RF-60TC PCB |

Tin Surface Finish PCB |

Taconic RF-60TC PCB |

OSP PCB Finish |

HASL PCB Finish |

|

|

|