|

|

|

|

|

|

|

Single-Sided-0.15mm-Polyimide-FPC--Shengyi-Laminate-with-3M-Tape-Tesa-Tape-Adhesive-Backed-for-Calculator-Keypads |

|

|

(FPC’s are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General description |

|

|

This single-layer flexible printed circuit features a 0.15mm thick , manufactured to IPC 6012 Class 2 standards using customer-provided Gerber data. Designed specifically for calculator keypad applications, the FPC incorporates 3M adhesive tape on the backside for secure mounting and assembly integration. |

|

|

|

|

|

Parameter and Data Sheet |

|

|

Size of Flexible PCB |

30.53 X 59.37mm |

Number of Layers |

1 |

Board Type |

Flexible PCB |

Board Thickness |

0.150mm |

Board Material |

Polyimide 25µm |

Board Material Supplier |

ITEQ |

Tg Value of Board Material |

60℃ |

|

PTH Cu thickness |

N/A |

Inner Iayer Cu thicknes |

N/A |

Surface Cu thickness |

35 µm |

|

|

Coverlay Colour |

Yellow |

Number of Coverlay |

2 |

Thickness of Coverlay |

25 µm |

Stiffener Material |

Polyimide |

Stiffener Thickness |

0.2mm |

|

|

Type of Silkscreen Ink |

IJR-4000 MW300 |

Supplier of Silkscreen |

TAIYO |

Color of Silkscreen |

White |

Number of Silkscreen |

1 |

|

Peeling test of Coverlay |

No peelable |

Legend Adhesion |

3M 90℃ No peeling after Min. 3 times test |

|

Surface Finish |

Immersion Gold |

Thickness of Nickle/Gold |

Au: 0.03µm(Min.); Ni 2-4µm |

RoHS Required |

Yes |

Famability |

94-V0 |

|

Thermal Shock Test |

Pass, -25℃±125℃, 1000 cycles. |

Thermal Stress |

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

Function |

100% Pass electrical test |

Workmanship |

Compliance with IPC-A-600H & IPC-6013C Class 2 |

|

|

|

|

|

|

.jpg) |

|

|

|

|

|

Features and Benefits

1. Excellent flexibility

2. Reducing the volume

3. Weight reduction

4. Consistency of assembly

5. Increased reliability

6. Low cost

7. Continuity of processing

8. The end can be whole soldered

9. Professional and experienced engineers

10. More than 20 years of experience |

|

|

|

|

|

Applications |

|

|

Touch screen, LED display soft board, Tablet antenna soft board |

|

|

|

|

|

Adhesives |

|

|

In the production of rigid printed circuit boards, base laminates are formed by laminating copper foils with base materials. During the lamination process, the adhesive is derived from the prepreg material. In contrast, for flexible circuits, the bonding of copper foil to the film material is accomplished using an adhesive system.

It's important to differentiate between two primary types of adhesives: thermoplastic adhesives and thermoset adhesives. The selection of an adhesive is influenced partly by the manufacturing process and partly by the intended use of the completed flexible circuit. |

|

|

|

|

|

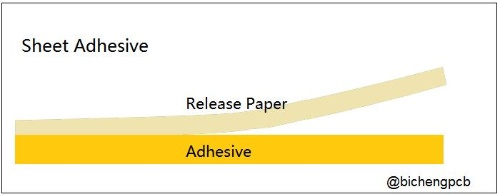

Sheets Adhesives / 3M Tape / Tesa Tape |

|

|

A sheet adhesive, often in the form of a low - flow acrylic, is an adhesive that is "cast" onto polypropylene paper. The adhesive can be easily peeled off from this paper. Sheet adhesives are commonly employed for integrating flexible circuits into multilayer flexible circuits or for attaching stiffeners to flexible circuits. |

|

|

|

|

|

|

|

|

|

|

|

More Displays of Flexible Circuits with 3M Tape |

|

|

.jpg) |

|

|

|

|

|

.jpg) |

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

Shengyi Polyimide Substrate |

Single-layer Flexible Printed Circuit |

0.15mm Thick Polyimide FPC |

FPC with 3M Adhesive Tape |

Flexible Circuits with 3M Tape |

|

|