|

|

|

|

|

|

Rogers RO4003C High Frequency PCB |

|

|

|

|

|

RO4003C materials are hydrocarbon resin system / ceramic filled laminates based on reinforced woven glass cloth. Its electrical properties are very close to PTFE/ woven glass |

|

|

cloth materials and the machinability is similar to epoxy resin / glass cloth materials. Its dielectric constant and loss are also strictly controlled. |

|

|

|

|

|

PCB Capability |

|

|

| |

| PCB Material: |

Glass reinforced hydrocarbon ceramic laminates |

| Code: |

Rogers RO4003C |

| Dielectric constant: |

3.38 ±0.05 (process) |

| |

3.55 (design) |

| Layer count: |

1 Layer, 2 Layer, Multilayer, Hybrid type (Mixed) |

| Copper weight: |

0.5oz (17 μm), 1oz (35μm), 2oz (70μm) |

| PCB thickness: |

10mil (0.254mm), 20mil (0.508mm) |

| |

30mil (0.762mm), 60mil (1.524mm) |

| PCB size: |

≤400mm X 500mm |

| Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

| Surface finish: |

Bare copper, HASL, ENIG, Immersion tin, OSP,etc. |

|

|

|

|

|

|

|

Double sided circuit boards on RO4003C are available in a variety of thicknesses, such as 12mil, 16mil, 20mil, 32mil and 60mil. It's used in a variety of typical and non-traditional |

|

|

microwave / radio frequency applications, such as base station antennas, power amplifiers, RFID, radar and sensors etc. |

|

|

|

|

|

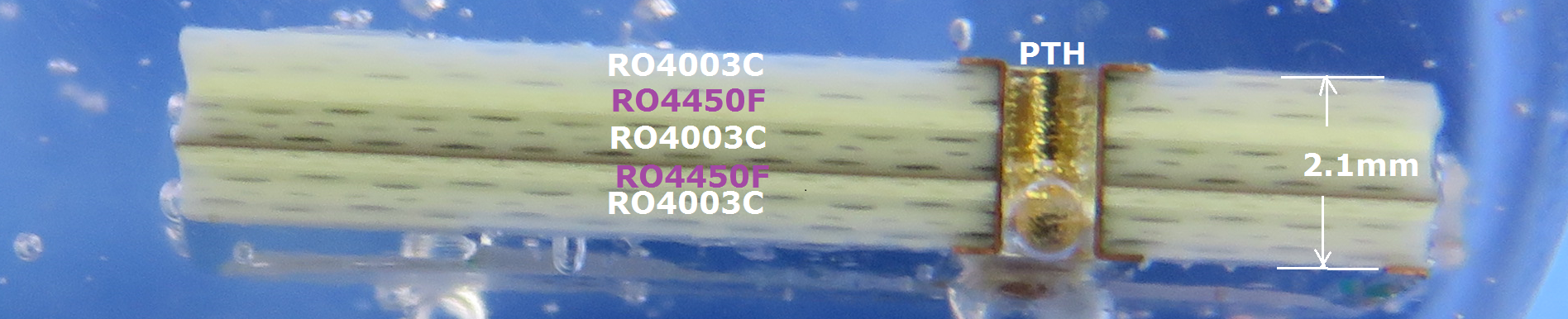

Multilayer circuit boards on RO4003C are widely used in the application of high reliability aerospace and its prepreg layer is also rogers bonding material ---RO4450F. |

|

|

|

|

|

In order to save production cost but not reduce signal loss in high frequency environment, mixed pressure production with FR-4 came into being. At present, the technology of |

|

|

mixed circuit board is mature and popular in the market. We can provide you with prototype and mass production service. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|