| |

|

|

|

|

|

|

|

|

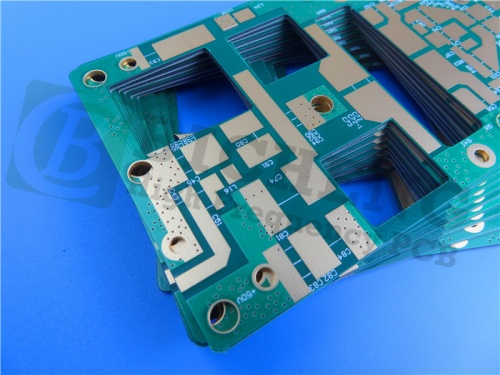

Rogers RT/duroid 5880LZ PCB 50mil 2-Layer 1.27mm 5880LZ High Frequency PCB Circuit Board with ENIG |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General Description |

|

|

Rogers RT/duroid 5880LZ PCB delivers high-frequency performance through its 50-mil-thick PTFE composite substrate, utilizing 0.5-ounce base copper processed to 1-ounce final thickness. RT/duroid 5880LZ PCB features a green solder-masked top layer and full-bottom-side immersion gold (ENIG) surface treatment, ensuring corrosion resistance and reliable solderability.

Manufactured to IPC Class 2 standards, 5880LZ PCB guarantees quality through 100% electrical testing via flying probe or custom fixtures before shipment. Designed for microwave systems, Rogers RT duroid 5880LZ PCB combines stable dielectric properties with enhanced copper weight to support precision RF circuits in radar and satellite communications. This PCB model’s ENIG-finished bottom layer and controlled impedance architecture make RT duroid 5880LZ PCB ideal for aerospace and defense applications requiring robust signal integrity. |

|

|

|

|

|

|

|

|

|

|

|

PCB Specifications |

|

|

PCB SIZE |

75 x 60mm=1up |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 17um(0.5 oz)+plate TOP layer |

|

RT/duroid 5880LZ 1.27mm |

|

copper ------- 17um(0.5 oz) + plate BOT Layer |

TECHNOLOGY |

|

Minimum Trace and Space: |

4 mil / 4 mil |

Minimum / Maximum Holes: |

0.4 mm / 3.0 mm |

Number of Different Holes: |

7 |

Number of Drill Holes: |

175 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

RT/duroid 5880LZ 1.27mm |

Final foil external: |

1.0 oz |

Final foil internal: |

N/A |

Final height of PCB: |

1.4 mm ±0.1 |

PLATING AND COATING |

|

Surface Finish |

Immersion Gold, 51.8% |

Solder Mask Apply To: |

Top side |

Solder Mask Color: |

Green |

Solder Mask Type: |

LPI |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

N/A |

Colour of Component Legend |

N/A |

Manufacturer Name or Logo: |

N/A |

VIA |

Plated through hole(PTH), minimum size 0.4mm. |

FLAMIBILITY RATING |

94V-0 |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

|

|

|

|

|

|

Our Advantages |

|

|

1.Wide range of high frequency materials, Rogers, Taconic and Wangling etc;

2.More than 19+ years’ high frequency PCB experience;

3.Strict WIP inspection and monitoring as well as working instruction;

4.16000㎡ workshop;

5.30000㎡ output capability per month;

6.8000 types of PCB's per month;

7.Small quantity order is available;

8.ISO9001, ISO14001, IATF16949, ISO13485, UL Certified;

9.IPC Class 2 / IPC Class 3;

10.Delivery on time: >98%, Customer complaint rate: <1% |

|

|

|

|

|

Our PCB Capabilities(2022) |

|

|

Parameter |

Value |

Layer Counts |

1-32 |

Substrate Material |

RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5; PTFE F4B (DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2); AD450, AD600, AD1000, TC350; Nelco N4000, N9350, N9240; FR-4 ( High Tg S1000-2M, TU-872 SLK, TU-768, IT-180A etc.), FR-4 High CTI>600V; Polyimide, PET; Metal Core etc. |

Maximum Size |

Flying test: 900*600mm, Fixture test 460*380mm, No test 1100*600mm |

Board Outline Tolerance |

±0.0059" (0.15mm) |

PCB Thickness |

0.0157" - 0.3937" (0.40mm--10.00mm) |

Thickness Tolerance(T≥0.8mm) |

±8% |

Thickness Tolerance(t<0.8mm) |

±10% |

Insulation Layer Thickness |

0.00295" - 0.1969" (0.075mm--5.00mm) |

Minimum Track |

0.003" (0.075mm) |

Minimum Space |

0.003" (0.075mm) |

Outer Copper Thickness |

35µm--420µm (1oz-12oz) |

Inner Copper Thickness |

17µm--350µm (0.5oz - 10oz) |

Drill Hole(Mechanical) |

0.0059" - 0.25" (0.15mm--6.35mm) |

Finished Hole(Mechanical) |

0.0039"-0.248" (0.10mm--6.30mm) |

DiameterTolerance(Mechanical) |

0.00295" (0.075mm) |

Registration (Mechanical) |

0.00197" (0.05mm) |

Aspect Ratio |

12:1 |

Solder Mask Type |

LPI |

Min Soldermask Bridge |

0.00315" (0.08mm) |

Min Soldermask Clearance |

0.00197" (0.05mm) |

Plug via Diameter |

0.0098" - 0.0236" (0.25mm--0.60mm) |

Impedance Control Tolerance |

±10% |

Surface Finish |

HASL,HASL LF,ENIG,Immersion Tin,Immersion Silver, OSP, Gold Finger, Pure gold plated etc. |

|

|

|

|

|

|

Appendix: Typical Value of RT/duroid 5880LZ |

|

Property |

Typical Value RT/duroid® 5880LZ |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant er,Process |

2.00 ± 0.04 |

Z |

|

10 GHz/23°C |

IPC-TM-650, 2.5.5.5 |

Dielectric Constant er,Design |

2.00 |

Z |

|

8 GHz - 40 GHz |

Differential Phase Length Method |

Dissipation Factor, tan |

Typ: 0.0021 Max: 0.0027 |

Z |

|

10GHz/23°C |

IPC-TM-650, 2.5.5.5 |

Thermal Coefficient of Dielectric Constant, er |

+20 |

Z |

ppm/°C |

-50°C to 150°C 10GHz |

IPC-TM-650, 2.5.5.5 |

Volume Resistivity |

1.74 X 10^7 |

|

Mohm•cm |

C-96/35/90 |

IPC-TM-650, 2.5.17.1 |

Surface Resistivity |

2.08 X 10^6 |

|

Mohm |

C-96/35/90 |

IPC-TM-650, 2.5.17.1 |

Electrical Strength |

40 |

|

KV |

D48/50 |

IPC-TM-650, 2.5.6 |

Dimensional Stability |

-0.38 |

X,Y |

% |

|

IPC-TM-650, 2.4.39A |

Moisture Absorption |

0.31 |

|

% |

24 hours/23°C |

IPC-TM-650, 2.6.2.1 |

Thermal Conductivity |

0.33 |

Z |

W/m/°K |

80°C |

ASTM C518 |

Coefficient of Thermal Expansion |

54, 47 40 |

X,Y Z |

ppm/°C |

0 to 150°C |

IPC-TM-650, 2.4.41 |

Outgassing |

|

|

|

|

TML |

0.01 |

|

% |

|

ASTM E-595 |

CVCM |

0.01 |

|

|

|

|

WVR |

0.01 |

|

|

|

|

Density |

1.4 |

|

gm/cm^3 |

|

ASTM D792 |

Copper Peel |

>4.0 |

|

pli |

|

IPC-TM-650, 2.4.8 |

Flammability |

V-O |

|

|

|

UL 94 |

Lead-Free Process Compatible |

YES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

2-Layer Rogers 5880LZ PCB |

RT/Duroid 5880LZ PCB Substrate |

Rogers 5880LZ High Frequency PCB |

RT/Duroid® 5880LZ PCB Laminates |

RT/Duroid Circuit Board |

|

|

|