| |

|

|

|

|

|

|

|

|

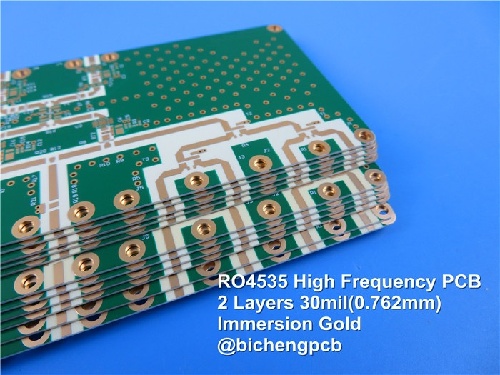

Rogers RO4535 High Frequency PCB 2-Layer 30mil 0.762mm Antenna Circuit Board with Immersion Gold |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General Description |

|

|

Rogers RO4535 PCB delivers high-frequency antenna solutions through its 30-mil substrate construction, starting with 0.5-ounce copper that's processed to achieve 1-ounce final thickness. RO4535 PCB features a green solder mask on its top layer and full-bottom-side immersion gold plating, ensuring corrosion-resistant surface performance.

Rogers RO4535 PCB meets IPC Class 2 requirements as a double-layer design, maintaining rigorous quality control through 100% electrical testing via flying probe or custom fixtures. Engineered for reliability, RO4535 laminate guarantees functional integrity from production to end-user delivery.

Optimized for RF applications, Rogers RO4535 PCB combines its enhanced copper weight and gold-plated bottom layer to support stable signal transmission in microwave systems. With its tested durability and standardized manufacturing, RO4535 substrate serves as a robust foundation for 5G infrastructure, IoT devices, and aerospace communication platforms. |

|

|

|

|

|

|

|

|

|

|

|

PCB Specifications |

|

|

PCB SIZE |

75 x 170mm=1up |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 17um(0.5 oz)+plate TOP layer |

|

Rogers RO4535 0.762mm |

|

copper ------- 17um(0.5 oz) + plate BOT Layer |

TECHNOLOGY |

|

Minimum Trace and Space: |

4 mil / 4 mil |

Minimum / Maximum Holes: |

0.3 mm / 3.0 mm |

Number of Different Holes: |

8 |

Number of Drill Holes: |

358 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

Rogers RO4535 0.762mm |

Final foil external: |

1.0 oz |

Final foil internal: |

N/A |

Final height of PCB: |

0.8 mm ±0.1 |

PLATING AND COATING |

|

Surface Finish |

Immersion Gold, 37.8% |

Solder Mask Apply To: |

Top side |

Solder Mask Color: |

Green |

Solder Mask Type: |

LPI |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

Component Side |

Colour of Component Legend |

White |

Manufacturer Name or Logo: |

N/A |

VIA |

Plated through hole(PTH), minimum size 0.3mm. |

FLAMIBILITY RATING |

94V-0 |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

|

|

|

|

|

|

Our Advantages |

|

|

1.Powerful PCB capabilities support your research and development, sales and marketing;

2.PCB Products and Manufacturing are certified by authorized organizations;

3.16000㎡ workshop with 30000㎡ output capability and 8000 types of PCB's per month;

4.Quick CADCAM checking and free PCB quotation;

5.No minimum order quantity. 1 piece is available;

6.A Team with passion, discipline, responsibility and honesty;

7.More than 19+ years of high frequency PCB experience;

8.Prototype PCB capability to Volume Production capability;

9.Delivery on time: >98%, Customer complaint rate: <1%

10.IPC Class 2 / IPC Class 3; |

|

|

|

|

|

Our PCB Capabilities(2022) |

|

|

Parameter |

Value |

Layer Counts |

1-32 |

Substrate Material |

RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5; PTFE F4B (DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2); AD450, AD600, AD1000, TC350; Nelco N4000, N9350, N9240; FR-4 ( High Tg S1000-2M, TU-872 SLK, TU-768, IT-180A etc.), FR-4 High CTI>600V; Polyimide, PET; Metal Core etc. |

Maximum Size |

Flying test: 900*600mm, Fixture test 460*380mm, No test 1100*600mm |

Board Outline Tolerance |

±0.0059" (0.15mm) |

PCB Thickness |

0.0157" - 0.3937" (0.40mm--10.00mm) |

Thickness Tolerance(T≥0.8mm) |

±8% |

Thickness Tolerance(t<0.8mm) |

±10% |

Insulation Layer Thickness |

0.00295" - 0.1969" (0.075mm--5.00mm) |

Minimum Track |

0.003" (0.075mm) |

Minimum Space |

0.003" (0.075mm) |

Outer Copper Thickness |

35µm--420µm (1oz-12oz) |

Inner Copper Thickness |

17µm--350µm (0.5oz - 10oz) |

Drill Hole(Mechanical) |

0.0059" - 0.25" (0.15mm--6.35mm) |

Finished Hole(Mechanical) |

0.0039"-0.248" (0.10mm--6.30mm) |

DiameterTolerance(Mechanical) |

0.00295" (0.075mm) |

Registration (Mechanical) |

0.00197" (0.05mm) |

Aspect Ratio |

12:1 |

Solder Mask Type |

LPI |

Min Soldermask Bridge |

0.00315" (0.08mm) |

Min Soldermask Clearance |

0.00197" (0.05mm) |

Plug via Diameter |

0.0098" - 0.0236" (0.25mm--0.60mm) |

Impedance Control Tolerance |

±10% |

Surface Finish |

HASL,HASL LF,ENIG,Immersion Tin,Immersion Silver, OSP, Gold Finger, Pure gold plated etc. |

|

|

|

|

|

Appendix: Typical Value of RO4535 |

|

Property |

RO4535 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant, er Process |

3.44 ± 0.08 |

Z |

- |

10 GHz/23℃ 2.5 GHz |

IPC-TM-650,2.5.5.5 |

Dissipation Factor |

0.0032 |

Z |

- |

2.5 GHz/23℃ |

IPC-TM-650, 2.5.5.5 |

|

0.0037 |

|

|

10 GHz/23℃ |

|

PIM (Typical) |

-157 |

- |

dBc |

Reflected 43 dBm swept tones |

Summitek 1900b PIM Analyzer |

Dielectric Strength |

>500 |

Z |

V/mil |

0.51 mm |

IPC-TM-650, 2.5.6.2 |

Dimensional Stability |

<0.5 |

X,Y |

mm/m (mils/inch) |

after etch |

IPC-TM-650, 2.4.39A |

Coefficient of Thermal Expansion |

16 |

X |

ppm/℃ |

-55 to 288℃ |

IPC-TM-650, 2.4.41 |

|

17 |

Y |

|

|

|

|

50 |

Z |

|

|

|

Thermal Conductivity |

0.6 |

- |

W/(m.K) |

80℃ |

ASTM C518 |

Moisture Absorption |

0.09 |

- |

% |

D48/50 |

IPC-TM-650, 2.6.2.1 ASTM D570 |

Tg |

>280 |

- |

℃ TMA |

A |

IPC-TM-650, 2.4.24.3 |

Density |

1.9 |

- |

gm/cm3 |

- |

ASTM D792 |

Copper Peel Strength |

5.1 (0.9) |

- |

lbs/in (N/mm) |

1 oz. EDC post solder float |

IPC-TM-650, 2.4.8 |

Flammability |

V-0 |

- |

- |

- |

UL 94 |

Lead-Free Process Compatible |

Yes |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

Rogers 4535 Circuit Board |

RO4535 High Frequency Antenna PCB |

Double Sided Rogers 4535 PCB |

Rogers 4535 30 Mil PCB |

Rogers 4535 Antenna PCB |

|

|

|