| |

|

|

|

|

|

|

|

|

Rogers Kappa 438 RF PCB Board 30mil 0.762mm Laminate DK 4.38 with Immersion Gold for Small Cells |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Brief Introduction |

|

|

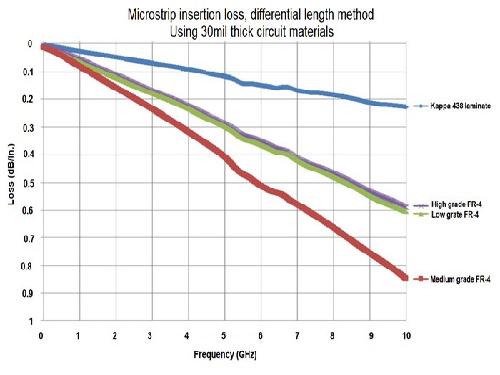

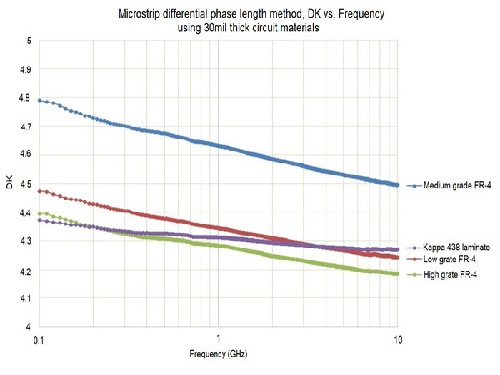

Designed for seamless migration from FR-4, Rogers Kappa 438 PCB offers tailored dielectric constants (Dk) that match FR-4 industry norms, allowing engineers to reuse over 80% of existing layouts while achieving significant electrical performance upgrades—reducing signal loss by 40% at 2.4 GHz. This makesKappa 438 PCB ideal for applications requiring balanced cost and high-frequency performance, such as 5G CPEs, industrial sensors, and consumer electronics.

The hydrocarbon-ceramic composite structure maintains the processing simplicity of FR-4 (e.g., standard dry film lamination, through-hole plating) while addressing its limitations in EMI suppression and impedance control. By combining FR-4’s manufacturability with microwave-grade performance, Kappa 438 laminate shortens development cycles for designers and lowers production costs for manufacturers without compromising reliability or compliance. |

|

|

|

|

|

Features |

|

|

1. Glass reinforced hydrocarbon thermoset platform

2. Dk of 4.38 is tailored to FR-4 industry standard norms

3. Tighter Dk and thickness tolerance than FR-4

4. Low Z Axis CTE of 42 ppm/°C

5. High Tg of > 280°C TMA

6. Meets UL 94-V0 requirements |

|

|

|

|

|

Benefits |

|

|

1. Ease of PCB manufacturing and assembly in Line with FR-4

2. Design Dk enables ease of converting existing FR-4 designs needing better electrical performance

3. Consistent circuit performance

4. Improved design flexibility and plated through-hole reliability

5. Automated assembly compatible |

|

|

|

|

|

.JPG) |

|

|

|

|

|

Typical Applications: |

|

|

1. Carrier Grade WiFi/Licensed Assisted Access (LAA)

2. Small Cell and Distributed Antenna Systems (DAS)

3. Vehicle to Vehicle/Vehicle to Infrastructure Communications (V2X)

4. Internet of Things (IoT)

Segments: Smart Home and Wireless Meters |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Our PCB Capability (Kappa 438) |

|

|

PCB Capability (Kappa 438) |

PCB Material: |

Glass Reinforced Hydrocarbon Ceramic |

Designation: |

Kappa 438 |

Dielectric constant: |

4.38 at 2.5GHz |

Layer count: |

Single Layer, Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

1oz (35 µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 60mil (1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersoin silver, Immersion tin, OSP, ENEPIG, Pure gold etc.. |

|

|

|

|

|

|

Data Sheet of Kappa 438 Laminate |

|

|

Property |

Typical Value Kappa 438 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant, er Design |

4.38 |

Z |

- |

2.5 GHz |

Differential Phase Length Method |

Dissipation Factor tan, d |

0.005 |

Z |

- |

10 GHz/23°C |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of Dielectric Constant e |

-21 |

- |

ppm/°C |

10 GHz (-50 to 150°C) |

Modified IPC-TM-650 2.5.5.5 |

Volume Resistivity |

2.9 x 109 |

- |

MΩ•cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

6.2 x 107 |

- |

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

675 |

Z |

V/mil |

- |

IPC-TM-650 2.5.6.2 |

Tensile Strength |

16 12 |

MD CMD |

kpsi |

- |

ASTM D3039/D3039-14 |

Flexural Strength |

25 19 |

MD CMD |

kpsi |

- |

IPC-TM-650 2.4.4 |

Dimensional Stability |

-0.48-0.59 |

MD CMD |

mm/m |

- |

IPC-TM-650 2.4.39a |

Coefficient of Thermal Expansion |

13 |

X |

ppm/°C |

-55 to 288°C |

IPC-TM-650 2.4.41 |

16 |

Y |

42 |

Z |

Thermal Conductivity |

0.64 |

Z |

W/(m.K) |

80°C |

ASTM D5470 |

Time to Delamination (T288) |

>60 |

- |

minutes |

288°C |

IPC-TM-650 2.4.24.1 |

Tg |

>280 |

- |

°C TMA |

- |

IPC-TM-650 2.4.24.3 |

Td |

414 |

- |

°C |

- |

IPC-TM-650 2.3.40 |

Moisture Absorption |

0.07 |

- |

% |

24/23 |

IPC-TM-650 2.6.2.1 |

Young’s Modulus |

2264 2098 |

MD CMD |

kpsi |

- |

ASTM D3039/D3039-14 |

Flex Modulus |

2337 2123 |

MD CMD |

kpsi |

- |

IPC-TM-650 2.4.4 |

Bow |

0.03 |

- |

% |

- |

IPC-TM-650 2.4.22C |

Twist |

0.08 |

- |

% |

- |

IPC-TM-650 2.4.22C |

Copper Peel Strength After Thermal Stress |

5.8 |

- |

lbs/in |

1 oz (35 µm) foil |

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

- |

- |

- |

UL 94 |

Specific Gravity |

1.99 |

- |

g/cm3 |

- |

ASTM D792 |

Lead-Free Process Compatible |

Yes |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

Hot Tags:

30 Mil Kappa 438 PCB |

30 Mil Rogers Material |

Kappa 438 High Frequency Board |

Rogers Kappa 438 30mil PCB |

Kappa 438 30mil Laminate |

|

|

|