|

|

|

|

|

|

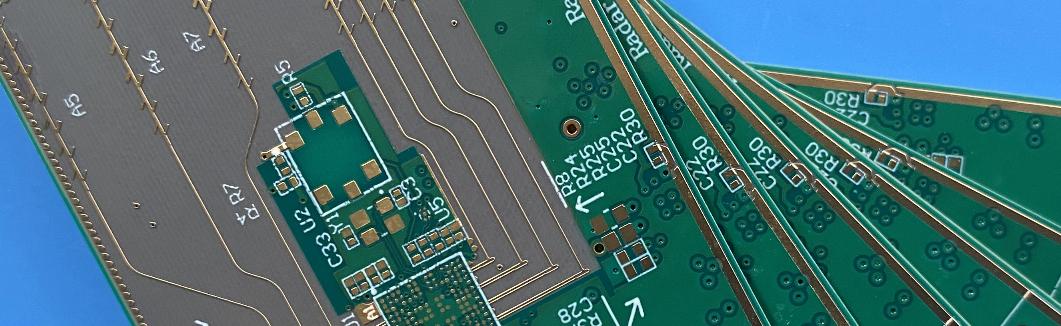

RT/duroid 5880LZ High Frequency PCB |

|

|

|

|

|

Rogers RT/duroid 5880LZ laminates are unique PTFE composites, which are designed for exacting stripline and microstrip circuit applications. The unique filler results in a low density, lightweight material for high performance and weight sensitive applications.The very low dielectric constant is uniform from panel to panel and is constant over a wide frequency range. Its low dissipation factor extends the usefulness to Ku-band and above. |

|

|

|

|

|

Features:

1. Lowest dielectric constant of 2.00 +/- 0.04

2. Low dissipation factor ranging from .0021 to .0027 at 10GHz

3. Low Z-axis coefficient of thermal expansion at 40 ppm/°C

4. Lightweight / low density of 1.4 gm/cm sq.

5. Uniform electrical properties over a wide frequency range

6. Resistant to all solvents and reagents, hot or cold, normally used in etching or plating |

|

|

|

|

|

Some Typical Applications:

1. Airborne antenna system

2. Lightweight feed networks

3. Military radar systems

4. Missile guidance systems

5. Point-to-point digital radio antenna

|

|

|

|

|

|

|

|

|

|

|

|

Our PCB Capability (RT/duroid 5880LZ)

|

|

|

| PCB Material: |

Unique PTFE Composites |

| Designation: |

RT/Duroid 5880LZ |

| Dielectric constant: |

2 |

| Dissipation Factor |

0.0021 10GHz |

| Layer count: |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

| Copper weight: |

0.5oz (17 μm), 1oz (35μm) |

| Laminate thickness: |

10mil (0.254mm), 20mil (0.508mm), 50mil (1.270mm), 100mil (2.540mm ) |

| PCB size: |

≤400mm X 500mm |

| Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

| Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc.. |

|

|

|

|

|

|

Typical Value of RT/duroid 5880LZ |

|

|

| Property |

Typical Value RT/duroid? 5880LZ |

Direction |

Units |

Condition |

Test Method |

| Dielectric Constant er,Process |

2.00 ± 0.04 |

Z |

|

10 GHz/23°C |

IPC-TM-650, 2.5.5.5 |

| Dielectric Constant er,Design |

2.00 |

Z |

|

8 GHz - 40 GHz |

Differential Phase Length Method |

| Dissipation Factor, tan? |

Typ: 0.0021 Max: 0.0027 |

Z |

|

10GHz/23°C |

IPC-TM-650, 2.5.5.5 |

| Thermal Coefficient of Dielectric Constant, er |

+20 |

Z |

ppm/°C |

-50°C to 150°C 10GHz |

IPC-TM-650, 2.5.5.5 |

| Volume Resistivity |

1.74 X 10^7 |

|

Mohm?cm |

C-96/35/90 |

IPC-TM-650, 2.5.17.1 |

| Surface Resistivity |

2.08 X 10^6 |

|

Mohm |

C-96/35/90 |

IPC-TM-650, 2.5.17.1 |

| Electrical Strength |

40 |

|

KV |

D48/50 |

IPC-TM-650, 2.5.6 |

| Dimensional Stability |

-0.38 |

X,Y |

% |

|

IPC-TM-650, 2.4.39A |

| Moisture Absorption |

0.31 |

|

% |

24 hours/23°C |

IPC-TM-650, 2.6.2.1 |

| Thermal Conductivity |

0.33 |

Z |

W/m/°K |

80°C |

ASTM C518 |

| Coefficient of Thermal Expansion |

54, 47 40 |

X,Y Z |

ppm/°C |

0 to 150°C? |

IPC-TM-650, 2.4.41 |

| Outgassing |

|

|

|

|

| TML |

0.01 |

|

% |

|

ASTM E-595 |

| CVCM |

0.01 |

|

|

| WVR |

0.01 |

|

|

| Density |

1.4 |

|

gm/cm^3 |

|

ASTM D792 |

| Copper Peel |

>4.0 |

|

pli |

|

IPC-TM-650, 2.4.8 |

| Flammability |

V-O |

|

|

|

UL 94 |

| Lead-Free Process Compatible |

YES |

|

|

|

|

|

|

|

|

|

|

|