| |

|

|

|

|

|

|

|

|

RO4360G2 High Frequency PCB Based on 6-layer with 8mil Core Coating Immersion Gold for Small Cell Transceivers From Rogers |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Rogers RO4360G2 PCBs are low-loss, high-performance materials with a dielectric constant (Dk) of 6.15. These thermoset materials, reinforced with glass and filled with hydrocarbon ceramic, provide an ideal blend of performance and processing ease. RO4360G2 laminates are lead-free compatible and offer improved rigidity, enhancing manufacturability in multi-layer board designs while reducing costs.

Processing similarly to FR-4, RO4360G2 substrates are compatible with automated assembly and feature a low Z-axis CTE for design flexibility. They share the high Tg of the RO4000 series and can be combined with RO4450F prepreg and lower-Dk RO4000 laminates in multi-layer designs.

With a Dk of 6.15 (Design Dk 6.4), RO4360G2 PCBs allow for compact circuit designs, making them ideal for size- and cost-sensitive applications. They are a cost-effective solution for power amplifiers, patch antennas, ground-based radar, and various RF applications, offering outstanding performance and value. |

|

|

|

|

|

Features and benefits: |

|

|

1. Advanced Thermoset Resin System for Dk 6.15 :

1). Easy fabrication with processing similar to FR-4.

2). Consistent material performance across batches.

3). Low dielectric loss for superior signal integrity.

4). High thermal conductivity for efficient heat dissipation.

5). Cost-effective solution compared to competing PTFE-based products.

2. Low Z-Axis CTE and High Tg:

1). Enhanced design flexibility.

2). Reliable plated through-hole performance.

3). Compatible with automated assembly processes.

3. Environmentally Friendly:

1). Lead free process compatible.

4. Regional Finished Goods Inventory:

1). Short lead times and fast inventory turnover.

2). Efficient supply chain management for timely delivery. |

|

|

|

|

|

Some Typical Applications: |

|

|

1. Base Station Power Amplifiers

2. Small Cell Transceivers

3. Patch antennas

4. Ground-based Radar |

|

|

|

|

|

新.jpg) |

|

|

|

|

|

RO4360G2 PCB Capability |

|

|

PCB Capability (RO4360G2) |

PCB Material: |

Hydrocarbon Ceramic-filled Thermoset Materials |

Designation: |

RO4360G2 |

Dielectric constant: |

6.15 ±0.15 |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

PCB thickness: |

8mil (0.203mm), 12mil (0.705mm), 16mil (0.406mm), 20mil(0.508mm), 24mil (0.610mm), 32mil (0.813mm), 60mil(1.524mm) |

|

|

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion tin, Immersion silver, Pure gold etc.. |

|

|

|

|

|

|

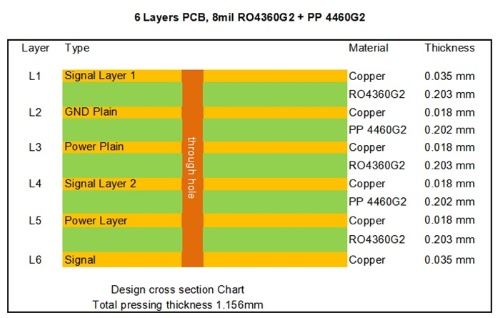

RO4360G2 Stack up |

|

|

|

|

|

|

|

|

Data Sheet of RO4360G2 |

|

|

RO4360G2 Typical Value |

Property |

RO4360G2 |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

6.15±0.15 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

|

|

|

|

2.5 GHz/23℃ |

|

Dissipation Factor,tanδ |

0.0038 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Conductivity |

0.75 |

|

W/mK |

50℃ |

ASTM D-5470 |

Volume Resistivity |

4.0 X 1013 |

|

Ω.cm |

Elevated T |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

9.0 X 1012 |

|

Ω |

Elevated T |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

784 |

Z |

V/mil |

|

IPC-TM-650 2.5.6.2 |

Tensile Strength |

131 (19) 97(14) |

X Y |

MPa (kpsi) |

40 hrs 50%RH/23 |

ASTM D638 |

Flexural Strength |

213(31) 145(21) |

X Y |

Mpa (kpsi) |

40 hrs 50%RH/23 |

IPC-TM-650, 2.4.4 |

Coefficient of Thermal Expansion |

13 14 28 |

X Y Z |

ppm/℃ |

-50 ℃to 288℃ After Replicated Heat Cycle |

IPC-TM-650, 2.1.41 |

Tg |

>280 |

|

℃ TMA |

|

IPC-TM-650 2.4.24.3 |

Td |

407 |

|

℃ |

|

ASTM D3850 using TGA |

T288 |

>30 |

Z |

min |

30 min / 125℃ Prebake |

IPC-TM-650 2.2.24.1 |

Moisure Absorption |

0.08 |

|

% |

50℃/48hr |

IPC-TM-650 2.6.2.1 ASTM D570 |

Thermal Coefficient of er |

-131 @10 GHz |

Z |

ppm/℃ |

-50℃ to 150 ℃ |

IPC-TM-650, 2.5.5.5 |

Density |

2.16 |

|

gm/cm3 |

RT |

ASTM D792 |

Copper Peel Stength |

5.2 (0.91) |

|

pli (N/mm) |

Condtion B |

IPC-TM-650 2.4.8 |

Flammability |

V-0 |

|

|

|

UL 94 File QMTS2. E102765 |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

8 Mil RO4360G2 PCB Thickness |

RO4360G2 Laminate for Sale |

RO4360G2 Dielectric Constant 6.15 |

Rogers RO4360G2 Material |

6-layer RO4360G2 RF PCB |

|

|

|