| |

|

|

|

|

|

|

|

|

RF-60A Taconic RF PCB 60mil 1.524mm Low Electrical Loss Organic Ceramic Laminate With Immersion Silver |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

RF - 60A, an organic - ceramic laminate in Taconic's Organic CERamic (ORCER) family, is reinforced by woven glass. Taconic's expertise in ceramic fill technology and coated PTFE fiberglass has given rise to this product. RF-60A PCB exhibits outstanding interlaminar bond strength and superior solder resistance. Its special composition leads to low moisture absorption and uniform electrical properties. |

|

|

|

|

|

|

|

|

|

|

|

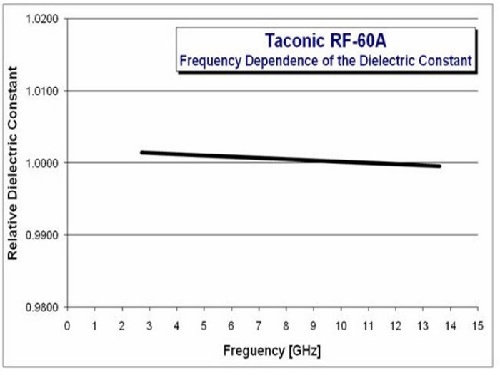

The woven glass reinforcement in RF - 60A laminate guarantees excellent dimensional stability and enhances flexural strength. It has a low Z - axis expansion, ensuring the reliability of plated - through - holes in severe thermal environments. With a dielectric constant of approximately 6.15, it is perfect for high DK products that demand a decrease in circuit size and weight. The low electrical loss factor makes it an excellent pick for RF circuits. |

|

|

|

|

|

|

|

|

|

|

|

RF - 60A laminates are in total compliance with RoHS and WEEE directives and are compatible with the temperatures of new lead - free solders. They can be sheared, drilled, milled, and plated by standard methods for PTFE - woven fiberglass materials, making it possible to achieve mass production. |

|

|

|

|

|

.jpg) |

|

|

|

|

|

Benefits (in general): |

|

|

Low Moisture Absorption

Stable DK over Frequency

Dimensionally Stable

Low Z-axis Expansion

High Flexural Strength

Exceptional Interlaminar Bonds |

|

|

|

|

|

Typical applications: |

|

|

Power Amplifiers

Filters & Couplers

Passive Components

Antennas |

|

|

|

|

PCB Capability (RF-60A) |

|

Our PCB Capability (RF-60A) |

PCB Material: |

Organic-ceramic Woven Fiberglass Reinforced Laminates |

Designation: |

RF-60A |

Dielectric constant: |

6.15 ±0.25 |

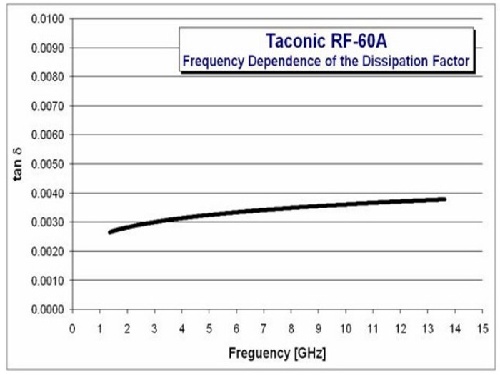

Dissipation Factor |

DF 0.0038@10 GHz |

Thermal Conductivity |

0.4 W/MK |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 25mil (0.635mm), 31mil (0.787mm), 50mil (1.27mm), 60mil (1.524mm), 125mil (3.175mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion tin etc.. |

|

|

|

|

Data Sheet of Taconic RF-60A |

|

RF-60A Typical Values |

Property |

Test Method |

Unit |

Value |

Unit |

Value |

Dk @ 10 GHz |

IPC-650 2.5.5.6 |

|

6.15 |

|

6.15 |

Df @ 10 GHz |

IPC-650 2.5.5.5.1 |

|

0.0038 |

|

0.0038 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.02 |

% |

0.02 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

53 |

kV |

53 |

Dielectric Strength |

ASTM D 149 |

V/mil |

880 |

kV/mm |

35 |

Volume Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm/cm |

9.0 x 108 |

Mohm/cm |

9.0 x 108 |

Surface Resistivity |

IPC-650 2.5.17.1 (After Humidity) |

Mohm |

2.28 x 108 |

Mohm |

2.28 x 108 |

Arc Resistance |

IPC-650 2.5.1 |

Seconds |

193 |

Seconds |

193 |

Flexural Strength (MD) |

ASTM D 790 |

psi |

18,300 |

N/mm2 |

126.2 |

Flexural Strength (CD) |

ASTM D 790 |

psi |

14,600 |

N/mm2 |

100.7 |

Tensile Strength (MD) |

ASTM D 3039 |

psi |

19,500 |

N/mm2 |

134.4 |

Tensile Strength (CD) |

ASTM D 3039 |

psi |

16,300 |

N/mm2 |

112.4 |

Young’s Modulus |

ASTM D 3039 |

kpsi |

1,590 |

N/mm2 |

11,000 |

Poisson’s Ratio |

ASTM D 3039 |

|

0.068 |

N/mm2 |

0.068 |

Compressive Modulus |

ASTM D 695 (23°C) |

kpsi |

338 |

|

2,330 |

Peel Strength (1 oz. ED) |

IPC-650 2.4.8 Sec. 5.2.2 (Thermal Stress) |

lbs/in |

8 |

N/mm |

1.4 |

Dimensional Stability (MD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

0.68 |

mm/M |

0.68 |

Dimensional Stability (CD) |

IPC-650 2.4.39 Sec. 5.4 (After Bake) |

mils/in |

1.05 |

mm/M |

1.05 |

Density (Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.79 |

g/cm3 |

2.79 |

Thermal Conductivity |

ASTM F 433 |

W/M*K |

0.4 |

W/M*K |

0.4 |

CTE (X axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

9 |

ppm/°C |

9 |

CTE (Y axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

8 |

ppm/°C |

8 |

CTE (Z axis) |

ASTM D 3386 (-30°C - 125°C) |

ppm/°C |

69 |

ppm/°C |

69 |

Outgassing (% TML) |

ASTM E 595* |

% |

0.02 |

% |

0.02 |

Outgassing (% CVCM) |

ASTM E 595* |

% |

0.00 |

% |

0.00 |

Outgassing (% WVR) |

ASTM E 595* |

% |

0.01 |

% |

0.01 |

Flammability Rating |

UL 94 |

|

V-0 |

|

V-0 |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

RF-60A High Frequency PCB |

RF-60A Low CTE PCB |

60Mil RF-60A PCB |

RF-60A PCB Online Purchase |

RF-60A Loss Tangent |

|

|

|