| |

|

|

|

|

|

|

|

|

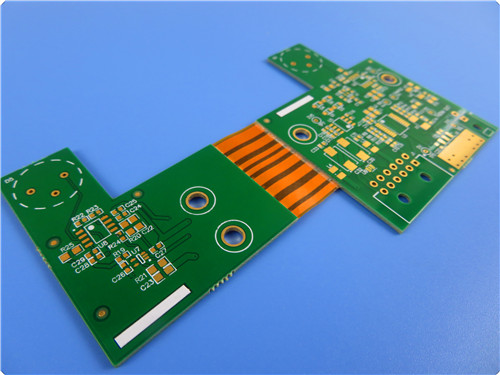

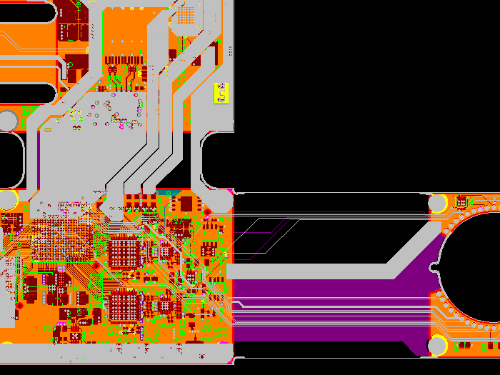

Low-Cost-FR-4-and-Polyimide-Based-8-Layer-Rigid-Flex-PCB-with-Immersion-Gold-and-50ohm- Impedance-Control |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General description |

|

|

This FR-4 and polyimide based rigid - flex PCB is specifically designed for car tracker GPS applications. It features an 8 - layer build - up structure. The rigid part has a thickness of 2.0mm, while the flexible part is 0.24mm thick. The inner layers use half - ounce copper, and the outer layers are made of 1 - ounce copper. In the inner flexible circuit, an impedance - controlled design is adopted to ensure stable electrical performance. For the pads, immersion gold plating is applied, which facilitates subsequent surface - mount technology (SMT) processes. The base laminates of this PCB are sourced from Shengyi and Thinflex. It is manufactured in accordance with IPC 6012 Class 2 standards, using the provided Gerber data to guarantee the accuracy and quality of the production. |

|

|

|

|

|

|

|

|

|

|

|

Basic specifications |

|

|

Size of Flex-Rigid PCB |

137mm x 178mm=1 PCS |

Number of Layers |

8 |

Board Type |

Rigid-Flex PCB |

Board Thickness |

2.0mm -Rigid, 0.24mm - flex |

Board Material |

FR-4 / Polyimide 3mil |

Board Material Supplier |

Shengyi / Panasonic |

Tg Value of Board Material |

170℃ |

PTH Cu thickness |

≥20 µm |

Inner Iayer Cu thicknes |

18 µm |

Surface Cu thickness |

35 µm |

Coverlay Colour |

Yellow coverlay / Green solder mask |

Number of Coverlay |

2 |

Thickness of Coverlay |

25 µm |

Stiffener Material |

N/A |

Stiffener Thickness |

N/A |

Type of Silkscreen Ink |

IJR-4000 MW300 |

Supplier of Silkscreen |

TAIYO |

Color of Silkscreen |

White |

Number of Silkscreen |

1 |

Peeling test of Coverlay |

No peelable |

Legend Adhesion |

3M 90℃ No peeling after Min. 3 times test |

Surface Finish |

Immersion Gold |

Thickness of Surface Finish |

Au: 0.03µm(Min.); Ni 2-4µm |

RoHS Required |

Yes |

Famability |

94-V0 |

Thermal Shock Test |

Pass, -25℃±125℃, 1000 cycles. |

Thermal Stress |

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

Function |

100% Pass electrical test |

Workmanship |

Compliance with IPC-A-600H & IPC-6013C Class 2 |

Stack-up |

Top Layer |

|

Inner layer 1 |

|

Inner layer 2 |

|

Inner layer 3 |

|

Inner layer 4 - inner flexible layer |

|

Inner layer 5 - inner flexible layer |

|

Inner layer 6 |

|

Bottom layer |

Impedance |

Controlled layer |

Referece layer |

Trace lines |

50 ohm±10% |

Top Layer |

IN1 |

0.15mm |

|

IN4 |

IN3/IN4 |

|

|

IN4 (Flex part) |

IN5 (Flex part) |

|

|

BOT |

IN6 |

|

80 ohm±10% |

TOP |

IN1 |

0.16mm/0.16mm |

|

IN4 |

IN3/IN5 |

0.19mm/0.16mm |

|

BOT |

IN6 |

0.16mm/0.16mm |

|

|

|

|

|

|

Applications |

|

|

Contact belt of inkjet printer, industrial surveying and mapping instrument, Tablet PC camera soft board |

|

|

|

|

|

Our Advantages |

|

|

Manufacturing Process |

|

|

• Cutting-edge Machinery: The production of rigid-flex PCBs relies on state-of-the-art manufacturing tools to achieve unparalleled precision. This includes high-accuracy drilling systems for creating intricate via holes with minimal deviation and advanced lamination apparatus that ensures seamless bonding between rigid and flexible layers, maintaining structural integrity and dimensional stability.

• Stringent Quality Assurance: Robust quality control protocols are implemented at every production stage. These involve multiple inspection checkpoints, such as thorough visual examinations to detect defects like delamination or misalignments, and comprehensive electrical testing to verify conductivity, impedance compliance, and signal integrity. This meticulous approach guarantees that the final product meets or exceeds industry standards for performance and reliability. |

|

|

|

|

|

Material Selection |

|

|

• Premium - Quality Materials: Select the highest - quality materials for the rigid and flexible components of the PCB. For the rigid part, high - Tg (glass transition temperature) substrates are employed. These substrates, such as those from Shengyi and ITEQ, offer superior heat resistance, which is crucial for maintaining the integrity of the PCB under high - temperature conditions. As for the flexible part, materials with outstanding flexibility and durability are chosen. Brands like Thinflex and Shengyi provide such materials, ensuring that the flex part can withstand repeated bending and other mechanical stresses.

• Material Harmony: Make sure that the materials used in the rigid and flexible sections are both chemically and mechanically in harmony. This compatibility is essential to avoid problems like delamination in the long run, guaranteeing the long - term stability and reliability of the PCB. |

|

|

|

|

|

Flexibility and Versatility |

|

|

• Diverse Application Suitability: Our production capabilities enable us to create PCBs tailored to a multitude of industries, such as aerospace, medical devices, and consumer electronics. Take the aerospace industry as an example. Rigid - flex PCBs find their application in flight control systems. Their unique properties allow them to be installed in confined spaces and endure vibrations, making them an ideal choice for such critical systems.

• Mastery of Complex Geometries: We have the proficiency to fabricate PCBs featuring intricate shapes and contours. This expertise opens the door to more innovative and space - saving designs. Consider miniature cameras, where the PCB can be precisely shaped to conform to the device's distinctive form factor, maximizing the utilization of available space. |

|

|

|

|

|

Cost-effective Offerings |

|

|

Our pricing strategy is structured to offer exceptional value without sacrificing quality. With no mandatory minimum order quantity and budget-friendly prototyping solutions, we cater to businesses of all scales—from small startups to large corporations—ensuring accessibility and flexibility for every project. This approach allows even those with limited resources to leverage our high-quality rigid-flex PCB manufacturing capabilities. |

|

|

|

|

|

Reliable Delivery |

|

|

Timeliness is a cornerstone of our service, as we consistently uphold an on-time delivery rate surpassing 98%. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

FR-4 and Polyimide Based PCB |

50ohm Impedance Control PCB |

PCB for GPS Applications |

High Tg FR-4 PCB |

8-Layer Rigid Flex PCB |

|

|

|