| |

|

|

|

|

|

|

|

|

High-Frequency PCB Coatings: Taonic TLY-5, TLY-5-L, TLY-3, and TLY-3FF with HASL, Immersion Gold, OSP, and Tin Finishes |

|

|

|

|

|

(As PCBs are custom - produced goods, the picture and parameters shown are only intended for reference.) |

|

|

|

|

|

Hello Everyone,

Today, we’re discussing high-frequency PCBs built on TLY materials.

TLY laminates, produced by Taconic, are made with lightweight woven fiberglass, offering superior dimensional stability compared to chopped fiber-reinforced PTFE composites. This enhanced mechanical stability makes them ideal for high-volume manufacturing.

With their low dissipation factor, TLY laminates are perfectly suited for automotive radar applications operating at 77 GHz, as well as other millimeter-wave frequency antennas. |

|

|

|

|

|

|

|

|

|

|

|

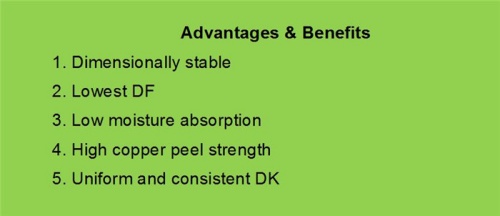

TLY laminates offer the following key advantages:

1. Superior Dimensional Stability:

Supports high-volume manufacturing with consistent results.

2. Ultra-Low Dissipation Factor:

A DF of ~0.0009 at 10 GHz minimizes signal loss in low-Dk applications.

3. Excellent Moisture Resistance:

Performs reliably in challenging environments, ensuring long-term stability.

4. High Copper Peel Strength:

With a peel strength of up to 2.32, it provides robust mechanical integrity.

5. Tight DK Tolerance:

A dielectric constant tolerance of +/-0.02 ensures uniformity and consistency across the board. |

|

|

|

|

|

|

|

|

|

|

|

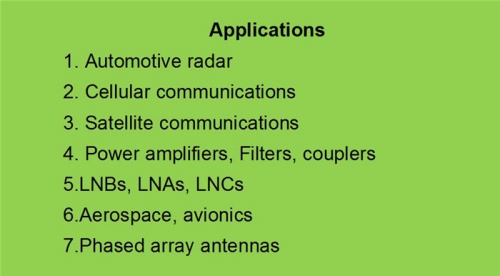

Typical Applications:

Automotive radar

Cellular communications

Satellite communications

Power amplifiers, filters, and couplers

LNBs, LNAs, and LNCs

Aerospace and avionics

Phased array antennas

The TLY family consists of 6 members. We currently stock TLY-5, while other variants are available for purchase based on client requirements. |

|

|

|

|

|

Our PCB Capability (TLY-5) |

|

|

PCB Capability (TLY-5) |

PCB Material: |

Lightweight Woven Fiberglass |

Designation: |

TLY-5 |

Dielectric Constant: |

2.2 |

Dissipation Factor |

0.0009 10GHz |

Layer Count: |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper Weight: |

1oz (35µm), 2oz (70µm) |

Laminate Thickness: |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

PCB Size: |

≤400mm X 500mm |

Solder Mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface Finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc.. |

|

|

|

|

|

|

At Bicheng, we provide comprehensive services, including prototype development, small-batch production, and mass manufacturing.

Should you have any inquiries, feel free to reach out to us.

Thank you for reading! |

|

|

|

|

|

Appendix: Typical Values of TLY |

|

|

TLY TYPICAL VALUES |

Property |

Test Method |

Unit |

Value |

Unit |

Value |

DK at 10 GHz |

IPC-650 2.5.5.5 |

|

2.2 |

|

2.2 |

Df at 10 GHz |

IPC-650 2.5.5.5 |

|

0.0009 |

|

0.0009 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.02 |

% |

0.02 |

Dielectric Breakdown |

IPC-650 2.5.6 |

kV |

>45 |

kV |

>45 |

Dielectric Strength |

ASTM D 149 |

V/mil |

2,693 |

V/mil |

106,023 |

Volume Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms/cm |

1010 |

Mohms/cm |

1010 |

Volume Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms/cm |

1010 |

Mohms/cm |

109 |

Surface Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms |

108 |

Mohms |

108 |

Surface Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms |

108 |

Mohms |

108 |

Flex Strength(MD) |

IPC-650 2.4.4 |

psi |

14,057 |

N/mm2 |

96.91 |

Flex Strength(CD) |

IPC-650 2.4.4 |

psi |

12,955 |

N/mm2 |

89.32 |

Peel Stength(½ oz.ed copper) |

IPC-650 2.4.8 |

Ibs./inch |

11 |

N/mm |

1.96 |

Peel Stength(1 oz.CL1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

16 |

N/mm |

2.86 |

Peel Stength(1 oz..CV1 copper) |

IPC-650 2.4.8 |

Ibs./inch |

17 |

N/mm |

3.04 |

Peel Stength |

IPC-650 2.4.8(after elevated temp.) |

Ibs./inch |

13 |

N/mm |

2.32 |

Young's Modulus(MD) |

ASTM D 3039/IPC-650 2.4.19 |

psi |

1.4 x 106 |

N/mm2 |

9.65 x 103 |

Poisson's Ratio(MD) |

ASTM D 3039/IPC-650 2.4.19 |

|

0.21 |

|

0.21 |

Thermal Conductivity |

ASTM F 433 |

W/M*K |

0.22 |

W/M*K |

0.22 |

Dimensional Stability(MD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.038 |

|

-0.038 |

Dimensional Stability(CD,10mil) |

IPC-650 2.4.39(avg.after bake&thermal stress) |

mils/inch |

-0.031 |

|

-0.031 |

Density(Specific Gravity) |

ASTM D 792 |

g/cm3 |

2.19 |

g/cm3 |

2.19 |

CTE(X axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

26 |

ppm/℃ |

26 |

CTE(Y axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

15 |

ppm/℃ |

15 |

CTE(Z axis)(25-260℃) |

ASTM D 3386(TMA) |

ppm/℃ |

217 |

ppm/℃ |

217 |

NASA Outgassing(% TML) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% CVCM) |

|

|

0.01 |

|

0.01 |

NASA Outgassing(% WVR) |

|

|

0.00 |

|

0.00 |

UL-94 Flammability Rating |

UL-94 |

|

V-0 |

|

V-0 |

|

|

|

|

|

|

Hot Tags:

Taconic TLY laminates |

TLY series PCB Datasheet |

Taonic TLY-5 PCB |

Taonic TLY-3 PCB |

Taconic TLY material |

|

|

|