| |

|

|

|

|

|

|

|

|

F4BM220 High-Frequency PCB 3.0mm PTFE DK 2.2 with 1oz Copper HASL Lead-Free for Superior Signal Integrity |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Hi everyone,

Today, let’s discuss a high-frequency circuit board from the F4BM series, specifically designed with a 3.0mm thickness.

The F4BM laminates are manufactured through a precise scientific process, combining fiberglass cloth, polytetrafluoroethylene resin, and polytetrafluoroethylene film under strict pressing conditions. Compared to the F4B series, the F4BM offers enhanced electrical performance, featuring a broader range of dielectric constants, reduced dielectric loss, higher insulation resistance, and improved stability. This makes it a reliable alternative to similar international products. |

|

|

|

|

|

Basic specifications |

|

|

Layer count: |

Double sided |

Base material: |

F4BM220 DK 2.2 |

Dimension: |

61 x 62mm |

Finished thickness |

3.0mm ±10% |

Finished Copper weight: |

1oz |

SMOBC: |

No |

Surface finish: |

HASL Pb free |

|

|

|

|

|

|

This board is designed as a double-sided PCB, utilizing F4BM220 as the substrate with a dielectric constant (DK) of 2.2. It measures 61mm in length and 62mm in width, with a finished thickness of 3.0mm. The board features a 1.0oz finished copper weight and comes without solder mask or silkscreen. The surface finish is OSP (Organic Solderability Preservative).

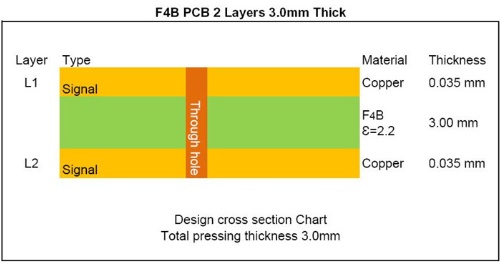

Now, let’s take a closer look at the stack-up details: |

|

|

|

|

|

|

|

|

The top and bottom layers are finished with 1oz copper. Positioned between these two copper layers is the F4BM220 dielectric material, which has a dielectric constant (DK) of 2.2 and a thickness of 3.0mm. |

|

|

|

|

|

.png) |

|

|

Here is the photo of this board. The standard color of the F4BM220 PCB is brown. |

|

|

|

|

|

Our PCB Capability (F4BM) |

|

|

PCB Capability (F4BM) |

PCB Material: |

PTFE glass fiber cloth copper clad laminates |

Designation (F4BM ) |

F4BM |

DK (10GHz) |

DF (10 GHz) |

|

F4BM217 |

2.17±0.04 |

0.0010 |

|

F4BM220 |

2.20±0.04 |

0.0010 |

|

F4BM233 |

2.33±0.04 |

0.0011 |

|

F4BM245 |

2.45±0.05 |

0.0012 |

|

F4BM255 |

2.55±0.05 |

0.0013 |

|

F4BM265 |

2.65±0.05 |

0.0013 |

|

F4BM275 |

2.75±0.05 |

0.0015 |

|

F4BM294 |

2.94±0.06 |

0.0016 |

|

F4BM300 |

3.00±0.06 |

0.0017 |

Layer count: |

Single Sided, Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

Dielectric thickness (or overall thickness) |

0.127mm (dielectric), 0.2mm, 0.25mm, 0.5mm, 0.508mm, 0.762mm, 0.8mm, 1.0mm, 1.5mm, 1.524mm, 1.575mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc.. |

|

|

|

|

|

|

The F4BM material provides a broad range of dielectric constants, from 2.17 to 3.0, and offers flexible board thickness options, ranging from 0.13mm to 12.0mm. We are fully capable of delivering end-to-end services, including prototype development, small-scale production, and large-volume manufacturing.

Should you have any questions, feel free to contact us. Thank you for your time and interest! |

|

|

|

|

|

Appendix: Data Sheet (F4BM) |

|

|

Product Technical Parameters |

Product Model & Data Sheet |

Product Features |

Test Conditions |

Unit |

F4BM217 |

F4BM220 |

F4BM233 |

F4BM245 |

F4BM255 |

F4BM265 |

F4BM275 |

F4BM294 |

F4BM300 |

Dielectric Constant (Typical) |

10GHz |

/ |

2.17 |

2.2 |

2.33 |

2.45 |

2.55 |

2.65 |

2.75 |

2.94 |

3.0 |

Dielectric Constant Tolerance |

/ |

/ |

±0.04 |

±0.04 |

±0.04 |

±0.05 |

±0.05 |

±0.05 |

±0.05 |

±0.06 |

±0.06 |

Loss Tangent (Typical) |

10GHz |

/ |

0.001 |

0.001 |

0.0011 |

0.0012 |

0.0013 |

0.0013 |

0.0015 |

0.0016 |

0.0017 |

20GHz |

/ |

0.0014 |

0.0014 |

0.0015 |

0.0017 |

0.0018 |

0.0019 |

0.0021 |

0.0023 |

0.0025 |

Dielectric Constant Temperature Coefficient |

-55ºC~150ºC |

PPM/℃ |

-150 |

-142 |

-130 |

-120 |

-110 |

-100 |

-92 |

-85 |

-80 |

Peel Strength |

1 OZ F4BM |

N/mm |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

1 OZ F4BME |

N/mm |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

Volume Resistivity |

Standard Condition |

MΩ.cm |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

Surface Resistivity |

Standard Condition |

MΩ |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

Electrical Strength (Z direction) |

5KW,500V/s |

KV/mm |

>23 |

>23 |

>23 |

>25 |

>25 |

>25 |

>28 |

>30 |

>30 |

Breakdown Voltage (XY direction) |

5KW,500V/s |

KV |

>30 |

>30 |

>32 |

>32 |

>34 |

>34 |

>35 |

>36 |

>36 |

Coefficientof Thermal Expansion |

XY direction |

-55 º~288ºC |

ppm/ºC |

25, 34 |

25, 34 |

22, 30 |

20, 25 |

16, 21 |

14, 17 |

14, 16 |

12, 15 |

12, 15 |

Z direction |

-55 º~288ºC |

ppm/ºC |

240 |

240 |

205 |

187 |

173 |

142 |

112 |

98 |

95 |

Thermal Stress |

260℃, 10s,3 times |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

No delamination |

Water Absorption |

20±2℃, 24 hours |

% |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

Density |

Room Temperature |

g/cm3 |

2.17 |

2.18 |

2.20 |

2.22 |

2.25 |

2.25 |

2.28 |

2.29 |

2.29 |

Long-Term Operating Temperature |

High-Low Temperature Chamber |

℃ |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

Thermal Conductivity |

Z direction |

W/(M.K) |

0.24 |

0.24 |

0.28 |

0.30 |

0.33 |

0.36 |

0.38 |

0.41 |

0.42 |

PIM |

Only applicable to F4BME |

dBc |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

Flammability |

/ |

UL-94 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

Material Composition |

/ |

/ |

PTFE, Fiberglass Cloth

F4BM paired with ED copper foil, F4BME paired with reverse-treated (RTF) copper foil. |

|

|

|

|

|

|

Hot Tags:

F4BM220 High Frequency PCB |

3.0mm F4BM220 PCB |

F4BM220 Printed Circuit Board |

F4BM Series Laminates |

F4BM PTFE PCB |

|

|

|