| |

|

|

|

|

|

|

|

|

Double Sided RF PCB 1.525mm 60mil Taconic RF-35TC High Frequency PCB with Immersion Gold |

|

|

|

|

|

(As PCBs are custom - produced goods, the picture and parameters shown are only intended for reference.) |

|

|

|

|

|

Hi,Everyone,

Today, we are excited to introduce the high - frequency PCB crafted with RF - 35TC.

RF - 35TC is a high - frequency material from Taconic company. It is composed of PTFE (Polytetrafluoroethylene) as the base, filled with ceramic and reinforced by fiberglass. |

|

|

|

|

|

PCB Specifications |

|

|

Layer count: |

Double sided |

Base material: |

RF-35TC DK 3.5 |

Dimension: |

105 x 87mm |

Finished thickness |

1.6mm ±10% |

Finished Copper weight: |

2 oz |

SMOBC: |

No |

Surface finish: |

Immersion Gold |

|

|

|

|

|

|

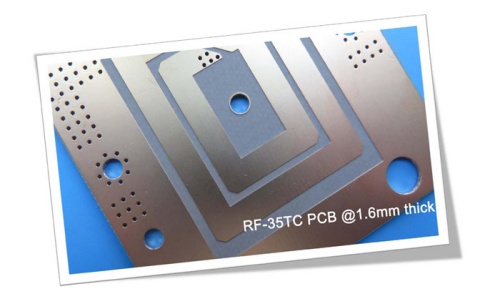

This is a double-sided PCB with an RF-35TC substrate and a dielectric constant of 3.5. It measures 105 mm in length and 87 mm in width, with a finished thickness of 1.6 mm and a copper weight of 2 oz. The PCB has no solder mask or silkscreen, and the surface finish is immersion gold.

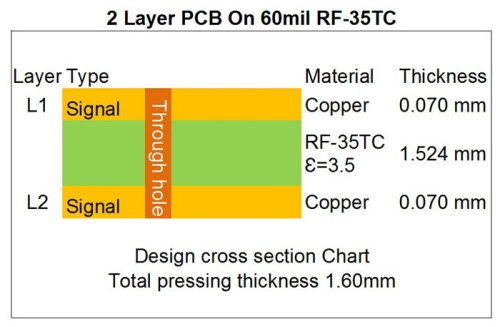

This is the stack-up drawing. |

|

|

|

|

|

|

|

|

The top and bottom layers consist of 2 oz finished copper, while the dielectric material, RF-35TC, is positioned in the middle with a thickness of 1.524 mm and a dielectric constant of 3.5. |

|

|

|

|

|

|

|

The RF-35TC PCB features a basic color of brown and grey. Its primary applications include power amplifiers, couplers, and filters, and it is also widely utilized in antennas and satellite equipment. |

|

|

|

Our PCB Capability (RF-35TC) |

|

|

PCB Material: |

PTFE based ceramic filled fiberglass substrate |

Designator: |

RF-35TC |

Dielectric constant @ 10GHz: |

3.50 |

|

|

Layer count: |

2 Layer, Multilayer, Hybrid type |

Copper weight: |

0.5oz, 1oz, 2oz |

PCB thickness: |

0.3mm, 0.6mm, 0.8mm, 1.6mm |

|

(10mil, 20mil, 30mil, 60mil substrate) |

Solder mask: |

Green, Red, Black, White, Blue etc. |

PCB size: |

≤400mm X 500mm |

Surface finish: |

Bare copper, HASL, ENIG, Immersion tin etc. |

|

|

|

|

|

|

|

|

We offer double-sided boards, multilayer boards, and hybrid boards, with thicknesses ranging from 0.3 mm to 1.6 mm and a maximum size of 400 mm by 500 mm. Available surface finishes include bare copper, hot air leveling, immersion gold, and more.

RF-35TC provides excellent heat dissipation, making it a thermally conductive, low-loss laminate ideal for high-power applications. It effectively dissipates heat from both the PCB transmission lines and surface-mounted components like capacitors.

If you have any questions, please don’t hesitate to contact us. Thank you for your attention! |

|

|

|

|

|

Appendix: Data Sheet RF-35TC |

|

|

RF-35TC TYPICAL VALUES |

Property |

Test Method |

Unit |

Value |

Unit |

Value |

DK @10 GHz |

IPC-650 2.5.5.5.1(modified) |

|

3.5 |

|

3.5 |

Tck(-30 to 120℃) |

IPC-650 2.5.5.5.1(modified) |

ppm |

24 |

ppm |

24 |

Df @10 GHz |

IPC-650 2.5.5.5.1(modified) |

|

0.0011 |

|

0.0011 |

Dielectric Breakdown |

IPC-650 2.5.6(in-Plane,Two Pins in Oil) |

kV |

56.7 |

kV |

56.7 |

Dielectric Strength |

ASTM D 149(Through Plane) |

V/mil |

570 |

V/mm |

22,441 |

Arc Resistance |

IPC-650 2.5.1 |

Seconds |

304 |

Seconds |

304 |

Moisture Absorption |

IPC-650 2.6.2.1 |

% |

0.05 |

% |

0.05 |

Flexural Strength(MD) |

ASTM D 790/IPC-650 2.4.4 |

psi |

12,900 |

N/mm2 |

88.94 |

Flexural Strength(CD) |

ASTM D 790/IPC-650 2.4.4 |

psi |

11,700 |

N/mm2 |

80.67 |

Tensile Strength(MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

psi |

9,020 |

N/mm2 |

62.19 |

Tensile Strength(CD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

psi |

7,740 |

N/mm2 |

53.37 |

Elongation at Break(MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

% |

1.89 |

N/mm |

1.89 |

Elongation at Break(CD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

% |

1.7 |

% |

1.7 |

Young's Modulus(MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

psi |

667,000 |

N/mm2 |

4,599 |

Young's Modulus(CD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

psi |

637,000 |

N/mm2 |

4,392 |

Poisson's Ratio(MD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

|

0.18 |

|

0.18 |

Poisson's Ratio(CD) |

ASTM D 3039/IPC-TM-650 2.4.19 |

|

0.23 |

|

0.18 |

Compressive Modulus |

ASTM D 695(23℃) |

psi |

560,000 |

N/mm2 |

3,861 |

Flexural Strength(MD) |

ASTM D 790/IPC-650 2.4.4 |

psi |

1.46 x 106 |

N/mm2 |

10,309 |

Flexural Strength(CD) |

ASTM D 790/IPC-650 2.4.4 |

psi |

1.50 x 106 |

N/mm2 |

10,076 |

Peel Stength(½ oz.CVH) |

IPC-650 2.4.8(Thermal Stress.) |

Ibs./inch |

7 |

g/cm3 |

1.25 |

Thermal Conductivity(Unclad,125℃) |

ASTM F433(Guarded Heat Flow) |

W/(mK) |

0.6 |

W/(mK) |

0.6 |

Thermal Conductivity(C1/C1,125℃) |

ASTM F433(Guarded Heat Flow) |

W/(mK) |

0.92 |

W/(mK) |

0.92 |

Thermal Conductivity(CH/CH,125℃) |

ASTM F433(Guarded Heat Flow) |

W/(mK) |

0.87 |

W/(mK) |

0.87 |

Dimensional Stability(MD) |

IPC-650-2.4.39 Sec.5.4(After Etch) |

mils/in. |

0.23 |

mm/M |

0.23 |

Dimensional Stability(CD) |

IPC-650-2.4.39 Sec.5.4(After Etch) |

mils/in. |

0.64 |

mm/M |

0.64 |

Dimensional Stability(MD) |

IPC-650-2.4.39 Sec.5.5(Thermal Stress.) |

mils/in. |

-0.04 |

mm/M |

-0.04 |

Dimensional Stability(CD) |

IPC-650-2.4.39 Sec.5.5(Thermal Stress.) |

mils/in. |

0.46 |

mm/M |

0.46 |

Surface Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms |

8.33 x 107 |

Mohms |

8.33 x 107 |

Surface Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms |

6.42 x 107 |

Mohms |

6.42 x 107 |

Volume Resistivity |

IPC-650 2.5.17.1(after elevated temp.) |

Mohms/cm |

5.19 x 108 |

Mohms/cm |

5.19 x 108 |

Volume Resistivity |

IPC-650 2.5.17.1(after humidity) |

Mohms/cm |

2.91 x 108 |

Mohms/cm |

2.91 x 108 |

CTE(X axis)(25-260℃) |

IPC-650 2.4.41/ASTM D 3386 |

ppm/℃ |

11 |

ppm/℃ |

11 |

CTE(Y axis)(25-260℃) |

IPC-650 2.4.41/ASTM D 3386 |

ppm/℃ |

13 |

ppm/℃ |

13 |

CTE(Z axis)(25-260℃) |

IPC-650 2.4.41/ASTM D 3386 |

ppm/℃ |

34 |

ppm/℃ |

34 |

Density |

ASTM D 792 |

g/cm3 |

2.35 |

g/cm3 |

2.35 |

Hardness |

ASTM D 2240(Shore D) |

|

79.1 |

|

79.1 |

Strain at Break(MD) |

ASTM D 790/IPC-650 2.4.4 |

% |

0.014 |

% |

0.014 |

Strain at Break(CD) |

ASTM D 790/IPC-650 2.4.4 |

% |

0.013 |

% |

0.013 |

Specific Heat |

ASTM E 1269-05,E 967-08,E968-02 |

j/(g℃) |

0.94 |

j/(g℃) |

0.94 |

Td(2% Weight Loss) |

IPC-650 2.4.24.6/TGA |

oF |

788 |

℃ |

420 |

Td(5% Weight Loss) |

IPC-650 2.4.24.6/TGA |

oF |

817 |

℃ |

436 |

|

|

|

|

|

|

Hot Tags:

Taconic RF-35TC Price |

1.525mm Taconic RF-35TC Thickness |

RF-35TC Material |

RF-35TC Loss Tangent |

RF-35TC Datasheet |

|

|

|