| |

|

|

|

|

|

|

|

|

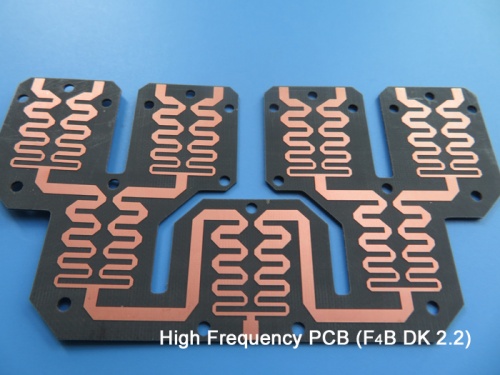

DK2.2 Dual Layer F4BME220 High Frequency PCB PTFE Cheap RF PWB for Couplers |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Brief Introduction

This PCB measures 100 x 100 mm and is designed as a double-sided, two-layer board. It accommodates surface mount components only, excluding through-hole components. The layer stackup features a top layer of 35 µm (1 oz) copper with an initial plating of 0.5 oz, paired with a 1.0 mm thick F4BME220 core material, and a matching bottom layer of 35 µm (1 oz) copper. The surface finish is Organic Solderability Preservative (OSP), ensuring reliable soldering performance. Notably, this PCB does not include a solder mask. |

|

|

|

|

|

The details are presented in the table below. |

|

|

|

|

|

PCB Specifications |

|

|

|

|

|

F4BME220 High Frequency PCB On DK2.2 Dual Layer Cheap RF PTFE PWB for Couplers |

|

|

PCB SIZE |

100 x 100mm=1PCS |

BOARD TYPE |

Double sided PCB |

Number of Layers |

2 layers |

Surface Mount Components |

YES |

Through Hole Components |

NO |

LAYER STACKUP |

copper ------- 35um(0.5 oz +plate) TOP layer |

F4BME220 1.0mm |

copper ------- 35um(0.5 oz + plate) BOT Layer |

TECHNOLOGY |

|

Minimum Trace and Space: |

10 mil / 10 mil |

Minimum / Maximum Holes: |

0.4 mm / 0.4 mm |

Number of Different Holes: |

1 |

Number of Drill Holes: |

1 |

Number of Milled Slots: |

0 |

Number of Internal Cutouts: |

0 |

Impedance Control: |

no |

Number of Gold finger: |

0 |

BOARD MATERIAL |

|

Glass Epoxy: |

F4BME220 DK 2.2 |

Final foil external: |

1oz |

Final foil internal: |

N/A |

Final height of PCB: |

1.1 mm ±10% |

PLATING AND COATING |

|

Surface Finish |

OSP |

Solder Mask Apply To: |

no |

Solder Mask Color: |

no |

Solder Mask Type: |

no |

CONTOUR/CUTTING |

Routing |

MARKING |

|

Side of Component Legend |

NO |

Colour of Component Legend |

NO |

Manufacturer Name or Logo: |

Marked on the board in a conductor and leged FREE AREA |

VIA |

Non-Plated through hole(PTH), minimum size 0.4mm. |

FLAMIBILITY RATING |

UL 94-V0 Approval MIN. |

DIMENSION TOLERANCE |

|

Outline dimension: |

0.0059" |

Board plating: |

0.0029" |

Drill tolerance: |

0.002" |

TEST |

100% Electrical Test prior shipment |

TYPE OF ARTWORK TO BE SUPPLIED |

email file, Gerber RS-274-X, PCBDOC etc |

SERVICE AREA |

Worldwide, Globally. |

|

|

|

|

F4BME High Frequency Laminates

F4BME series laminates are engineered through a precise formulation and rigorous pressing of fiberglass cloth, polytetrafluoroethylene resin, and polytetrafluoroethylene film. These laminates offer enhanced electrical performance compared to F4B, featuring a broader range of dielectric constants, reduced dielectric loss, increased insulation resistance, and improved stability. They serve as suitable replacements for similar foreign products. |

|

|

|

|

|

Features

◆ DK2.17 ~ 3.0 is optional, and DK can be customized

◆ Low loss

◆ F4BME with RTF copper foil has excellent PIM index

◆ Diversified size and cost saving

◆ Irradiation resistance and low exhaust

◆ Commercialization, mass production and high cost performance |

|

|

|

|

|

Typical Applications

◆ Microwave, RF, radar

◆ Phase shifter, passive components

◆ Power divider, coupler and combiner

◆ Feed network, phased array antenna

◆ Satellite communication, base station antenna |

|

|

|

|

|

Our PCB Capability(F4BME) |

|

|

PCB Capability (F4BME) |

PCB Material: |

PTFE glass fiber cloth copper clad laminates |

Designation (F4BME ) |

F4BME |

DK (10GHz) |

DF (10 GHz) |

|

F4BME217 |

2.17±0.04 |

0.0010 |

|

F4BME220 |

2.20±0.04 |

0.0010 |

|

F4BME233 |

2.33±0.04 |

0.0011 |

|

F4BME245 |

2.45±0.05 |

0.0012 |

|

F4BME255 |

2.55±0.05 |

0.0013 |

|

F4BME265 |

2.65±0.05 |

0.0013 |

|

F4BME275 |

2.75±0.05 |

0.0015 |

|

F4BME294 |

2.94±0.06 |

0.0016 |

|

F4BME300 |

3.00±0.06 |

0.0017 |

Layer count: |

Single Sided, Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

Dielectric thickness (or overall thickness) |

0.127mm (dielectric), 0.2mm, 0.25mm, 0.5mm, 0.508mm, 0.762mm, 0.8mm, 1.0mm, 1.5mm, 1.524mm, 1.575mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold, ENEPIG etc.. |

|

|

|

Data Sheets (F4BME) |

|

|

Product Technical Parameters |

Product Model & Data Sheet |

Product Features |

Test Conditions |

Unit |

F4BME

217 |

F4BME

220 |

F4BME

233 |

F4BME

45 |

F4BME

255 |

F4BME

265 |

F4BME

275 |

F4BME

294 |

F4BME

300 |

Dielectric Constant (Typical) |

10GHz |

/ |

2.17 |

2.2 |

2.33 |

2.45 |

2.55 |

2.65 |

2.75 |

2.94 |

3.0 |

Dielectric Constant Tolerance |

/ |

/ |

±0.04 |

±0.04 |

±0.04 |

±0.05 |

±0.05 |

±0.05 |

±0.05 |

±0.06 |

±0.06 |

Loss Tangent (Typical) |

10GHz |

/ |

0.001 |

0.001 |

0.0011 |

0.0012 |

0.0013 |

0.0013 |

0.0015 |

0.0016 |

0.0017 |

|

20GHz |

/ |

0.0014 |

0.0014 |

0.0015 |

0.0017 |

0.0018 |

0.0019 |

0.0021 |

0.0023 |

0.0025 |

Dielectric Constant Temperature Coefficient |

-55ºC~150ºC |

PPM/℃ |

-150 |

-142 |

-130 |

-120 |

-110 |

-100 |

-92 |

-85 |

-80 |

Peel Strength |

1 OZ F4BM |

N/mm |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

>1.8 |

|

1 OZ F4BME |

N/mm |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

>1.6 |

Volume Resistivity |

Standard Condition |

MΩ.cm |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

≥6×10^6 |

Surface Resistivity |

Standard Condition |

MΩ |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

≥1×10^6 |

Electrical Strength (Z direction) |

5KW,500V/s |

KV/mm |

>23 |

>23 |

>23 |

>25 |

>25 |

>25 |

>28 |

>30 |

>30 |

Breakdown Voltage (XY direction) |

5KW,500V/s |

KV |

>30 |

>30 |

>32 |

>32 |

>34 |

>34 |

>35 |

>36 |

>36 |

Coefficientof Thermal Expansion |

XY direction |

-55 º~288ºC |

ppm/ºC |

25, 34 |

25, 34 |

22, 30 |

20, 25 |

16, 21 |

14, 17 |

14, 16 |

12, 15 |

12, 15 |

|

Z direction |

-55 º~288ºC |

ppm/ºC |

240 |

240 |

205 |

187 |

173 |

142 |

112 |

98 |

95 |

Thermal Stress |

260℃, 10s,3 times |

No delamination

|

Water Absorption |

20±2℃, 24 hours |

% |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.08 |

Density |

Room Temperature |

g/cm3 |

2.17 |

2.18 |

2.20 |

2.22 |

2.25 |

2.25 |

2.28 |

2.29 |

2.29 |

Long-Term Operating Temperature |

High-Low Temperature Chamber |

℃ |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

-55~+260 |

Thermal Conductivity |

Z direction |

W/(M.K) |

0.24 |

0.24 |

0.28 |

0.30 |

0.33 |

0.36 |

0.38 |

0.41 |

0.42 |

PIM |

Only applicable to F4BME |

dBc |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

≤-159 |

Flammability |

/ |

UL-94 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

V-0 |

Material Composition |

/ |

/ |

PTFE, Fiberglass Cloth

F4BM paired with ED copper foil, F4BME paired with reverse-treated (RTF) copper foil. |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

| Dual Layer F4BME220 PCB |

DK 2.2 Wangling Substrate |

F4BME220 High Frequency PCB |

F4BME220 PCB Datasheet |

Low Dielectric Loss PCB |

|

|

|