| |

|

|

|

|

|

|

|

|

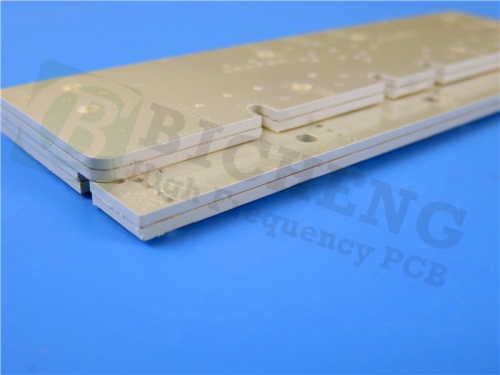

60mil Rogers TC350 PCB Low Loss Circuit Board with Immersion Gold for Thermally Cycled Antennas |

|

|

(Printed Circuit Boards are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

Rogers TC350 laminate is a composite composed of woven fiberglass reinforcement, ceramic filling, and a PTFE base, being used for printed circuit board fabrication. TC350 PCB is purposely designed to ensure enhanced heat - transfer via its "Best - In - Class" thermal conductivity. Moreover, it is made to reduce dielectric loss and insertion loss. Lower losses, in turn, lead to an elevation in amplifier and antenna gains and an improvement in their efficiencies. |

|

|

|

|

|

|

|

|

Features and Benefits: |

|

|

Rogers TC350 PCB 's enhanced thermal conductivity empowers it to manage greater power loads, eliminate thermal bottlenecks, and fortify device durability. By effectively lowering junction temperatures, it prolongs the lifespan of active components, playing a pivotal role in boosting power amplifier dependability, increasing the mean time between failures (MTBF), and cutting down on warranty expenses.

TC350 substrate demonstrates outstanding dielectric constant consistency throughout an extensive temperature spectrum. This characteristic enables power amplifier and antenna designers to optimize gain and minimize bandwidth wastage caused by dielectric constant fluctuations as the operating temperature varies.

TC350 laminate forms a robust connection with microwave - grade, low - profile copper. Thanks to this strong bond, it further reduces insertion loss, addressing the skin effect losses of copper that become more pronounced at higher RF and microwave frequencies. |

|

|

|

|

|

PCB Capability (TC350) |

|

|

Our PCB Capability (TC350) |

PCB Material: |

Woven Fiberglass Reinforced, Ceramic Filled, PTFE based Composite |

Designation: |

TC350 |

Dielectric constant: |

3.5±0.05 |

Thermal Conductivity |

0.72 W/m-K |

Dissipation Factor |

Df .002@10 GHz |

Layer count: |

Single Layer, Double Layer, Multi-layer, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion silver, Immersion tin, ENEPIG, Pure gold etc.. |

|

|

|

|

|

|

Typical applications: |

|

|

1. Microwave Combiner and Power Dividers

2. Power Amplifiers, Filters and Couplers

3. Tower Mounted Amplifiers (TMA) and Tower Mounted Boosters (TMB)

4. Thermally Cycled Antennas sensitive to dielectric drift |

|

|

|

|

Typical Properties of TC350 PCB |

|

Typical Properties:TC350 |

Property |

Units |

Value |

Test Merthod |

1. Electrical Properties |

|

Dielectric Constant (may vary by thickness) |

|

|

|

@1 MHz |

- |

3.50 |

IPC TM-650 2.5.5.3 |

@1.8 GHz |

- |

3.50 |

RESONANT CAVITY |

@10 GHz |

- |

3.50 |

IPC TM-650 2.5.5.5 |

Dissipation Factor |

|

|

|

@1 MHz |

- |

0.0015 |

IPC TM-650 2.5.5.3 |

@1.8 GHz |

- |

0.0018 |

RESONANT CAVITY |

@10 GHz |

- |

0.0020 |

IPC TM-650 2.5.5.5 |

Temperature Coefficient of Dielectric |

- |

|

|

TC r @ 10 GHz (-40-150°C) |

ppm/ºC |

-9 |

IPC TM-650 2.5.5.5 |

Volume Resistivity |

|

|

|

C96/35/90 |

MΩ-cm |

7.4x106 |

IPC TM-650 2.5.17.1 |

E24/125 |

MΩ-cm |

1.4x108 |

|

Surface Resistivity |

|

|

|

C96/35/90 |

MΩ |

3.2x107 |

IPC TM-650 2.5.17.1 |

E24/125 |

MΩ |

4.3x108 |

IPC TM-650 2.5.17.1 |

Electrical Strength |

Volts/mil (kV/mm) |

780 (31) |

IPC TM-650 2.5.6.2 |

Dielectric Breakdown |

kV |

40 |

IPC TM-650 2.5.6 |

Arc Resistance |

sec |

>240 |

IPC TM-650 2.5.1 |

2.Thermal Properties |

|

Decomposition Temperature (Td) |

|

|

|

Initial |

°C |

520 |

IPC TM-650 2.4.24.6 |

5% |

°C |

567 |

IPC TM-650 2.4.24.6 |

T260 |

min |

>60 |

IPC TM-650 2.4.24.1 |

T288 |

min |

>60 |

IPC TM-650 2.4.24.1 |

T300 |

min |

>60 |

IPC TM-650 2.4.24.1 |

Thermal Expansion, CTE (x,y) 50-150ºC |

ppm/ºC |

7, 7 |

IPC TM-650 2.4.41 |

Thermal Expansion, CTE (z) 50-150ºC |

ppm/ºC |

23 |

IPC TM-650 2.4.24 |

% z-axis Expansion (50-260ºC) |

% |

1.2 |

IPC TM-650 2.4.24 |

3. Mechanical Properties |

|

Peel Strength to Copper (1 oz/35 micron) |

|

|

|

After Thermal Stress |

lb/in (N/mm) |

7 (1.2) |

IPC TM-650 2.4.8 |

At Elevated Temperatures (150ºC) |

lb/in (N/mm) |

9 (1.6) |

IPC TM-650 2.4.8.2 |

After Process Solutions |

lb/in (N/mm) |

7 (1.2) |

IPC TM-650 2.4.8 |

Young’s Modulus |

kpsi (MPa) |

|

IPC TM-650 2.4.18.3 |

Flexural Strength (Machine/Cross) |

kpsi (MPa) |

14/10 (97/69) |

IPC TM-650 2.4.4 |

Tensile Strength (Machine/Cross) |

kpsi (MPa) |

11/8 (76/55) |

IPC TM-650 2.4.18.3 |

Compressive Modulus |

kpsi (MPa) |

|

ASTM D-3410 |

Poisson’s Ratio |

- |

|

ASTM D-3039 |

4. Physical Properties |

|

Water Absorption |

% |

0.05 |

IPC TM-650 2.6.2.1 |

Density, ambient 23ºC |

g/cm3 |

2.30 |

ASTM D792 Method A |

Thermal Conductivity |

W/mK |

0.72 |

ASTM D5470 |

Specific Heat |

J/gK |

0.90 |

ASTM D5470 |

Flammability |

class |

V-0 |

UL-94 |

NASA Outgassing, 125ºC, ≤10- 6 torr |

|

|

|

Total Mass Loss |

% |

0.02 |

NASA SP-R-0022A |

Collected Volatiles |

% |

0.01 |

NASA SP-R-0022A |

Water Vapor Recovered |

% |

0.01 |

NASA SP-R-0022A |

|

|

|

|

|

|

|

|

|

|

|

|

Hot Tags:

30mil TC350 PCB Material |

TC350 Rogers RF PCB |

Rogers Double Sided TC350 PCB |

TC350 Rogers PCB |

TC350 PCB Immersion Gold |

|

|

|