| |

|

|

|

|

|

|

|

|

6-Layer-High-Frequency-Hybrid-PCB-20mil-0.508mm-Rogers-RO4350B-and-FR-4-with-Blind-Via-and-Green-Solder-Mask |

|

|

|

|

|

(As PCBs are custom - produced goods, the picture and parameters shown are only intended for reference.) |

|

|

|

|

|

Hello everyone,

Good day!

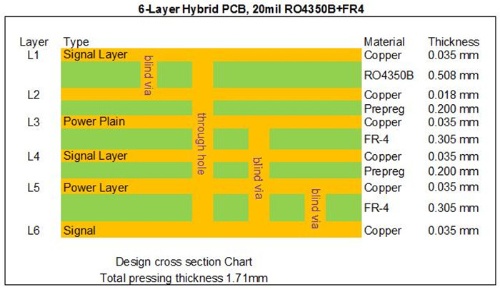

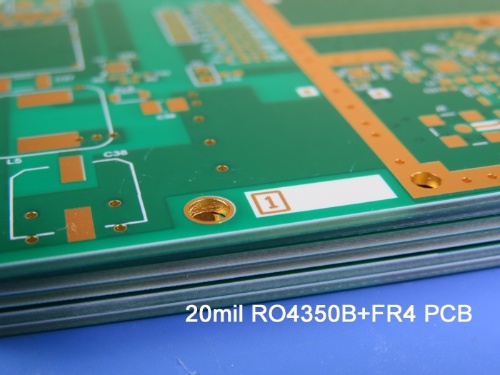

Today’s focus is on a 6-layer hybrid PCB constructed with a 20mil RO4350B core and FR-4 material. In this article, we’ll explore two distinct board designs. The first board is designed for satellite receiver applications. It features a single RO4350B core on the top layer, as illustrated in the stack-up below. The design is relatively complex, incorporating three different types of blind vias. The board has a total thickness of 1.71mm, with white silkscreen printed over green solder mask on both sides. Pads and tracks are finished with immersion gold plating. Each unit is supplied as a single board, manufactured in compliance with IPC 6012 Class 2 standards using provided Gerber files. For shipping, the boards are packed in sets of 25 per shipment. |

|

|

|

|

|

|

|

|

|

|

|

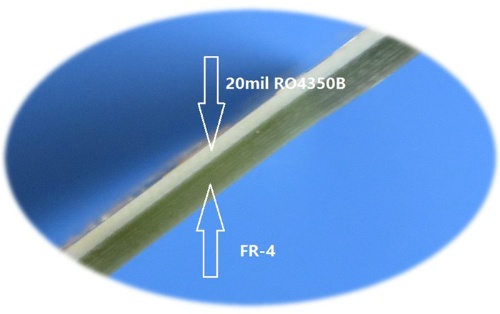

The following enlarged image provides a side view of the structure. |

|

|

|

|

|

|

|

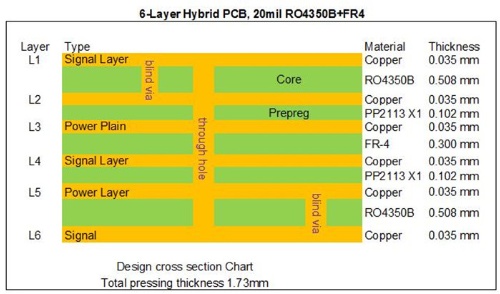

The second board is designed for signal booster applications. It utilizes two 20mil RO4350B cores, positioned on the top and bottom layers respectively. Refer to the stack-up diagram below for further details. |

|

|

|

|

|

|

|

|

The specifications are as follows:

Base material: RO4350B 20mil + FR4

Layer count: 6 layers

Type: Blind via L1-L2, L5-L6

Format: 100mm x 120mm = 1 type = 1 piece

Surface finish: Immersion gold

Copper weight: Outer layer 35 μm| Inner layer 35 μm

Solder mask | Legend: Green | White

Final PCB height: 1.8 mm

Standard: IPC 6012 Class 2

Packing: 20 panels are packed for shipment.

Lead time: 20 working days

Shelf life: 6 months |

|

|

|

|

|

|

|

|

|

|

|

RO4350B hybrid PCBs have a broad range of applications, including but not limited to: low-noise amplifiers (LNA), radar data acquisition converters, spread spectrum systems, 4G antennas, transmitters, RF switches, and splitter modules, among others. |

|

|

|

|

|

RO4350B hybrid PCBs offer numerous benefits |

|

|

1. RO4350B maintains a stable dielectric constant across a wide frequency range;

2. Enhanced signal integrity compared to stack-ups using only FR4 materials;

3. Cost-effective solution compared to designs relying entirely on low-loss materials;

4. Robust manufacturing capability, producing over 8,000 types of PCBs monthly;

5. Certified manufacturing facility compliant with ISO9001, ISO14001, IATF16949, and UL standards;

6. No minimum order quantity (MOQ), offering affordable options for prototypes and small-batch production.

Thank you for taking the time to read this. If you have any inquiries regarding RF PCBs, please feel free to contact us. |

|

|

|

|

|

Appendix: Our PCB Capability 2021 |

|

|

Factory Process Capability (2024) |

Substrate Types and Brands |

Standard FR-4, High Tg FR-4, High Frequency Materials, Polyimide/PET flexible Materials |

|

Shengyi, ITEQ, Isola, Taiwan Union, Rogers Corp. Taconic, Panasonic |

Board Types |

Rigid PCB, Flexible Circuits, Rigid-Flex PCB, Hybrid PCB, HDI PCB |

CCL Model |

High Tg FR-4: S1000-2M, TU-872 SLK, TU-768, IT-180A High CTI FR-4: S1600L, ST115 |

|

Rogers Corp: RO4350B, RO4003C, RO4725JXR, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4830, RO4835, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/duroid 6006, RT/Duroid 6010.2LM, RT/duroid 6035HTC; RT/duroid 5880LZ, RT/duroid 6202; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000, TC350; TC600; DiClad 880, DiClad 870, DiClad 527; IsoClad 917, IsoClad 933; CLTE-XT, CLTE-AT, CLTE-MW; CuClad 217, CuClad 233, CuClad 250. |

|

Taconic: TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2,RF-30, RF-35, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5, TLY-5Z; CER-10; TSM-DS3 |

|

Wangling: F4BM217, F4BM220, F4BM233, F4BM245, F4BM255, F4BM265, F4BM275, F4BM294, F4BM300;

F4BME217, F4BME220, F4BME233, F4BME245, F4BME255, F4BME265, F4BME275, F4BME294, F4BME300;

F4BTM298, F4BTM300, F4BTM320, F4BTM350;

F4BTME298, F4BTME300, F4BTME320, F4BTME350;

TP300, TP440, TP600, TP615, TP960, TP1020, TP1100, TP1600, TP2000, TP2200, TP2500;

TF300, TF440, TF600, TF960, TF1020, TF1600;

F4BTMS220, F4BTMS233, F4BTMS255, F4BTMS265, F4BTMS294, F4BTMS300, F4BTMS350, F4BTMS430, F4BTMS450, F4BTMS615, F4BTMS1000;

TFA294, TFA300, TFA615, TFA1020;

WL-CT300, WL-CT330, WL-CT330Z, WL-CT338, WL-CT350, WL-CT440, WL-CT615. Dielectric constant ranges DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2 |

Maximum Delivery Size |

1200mm x 572 mm |

Minimum Finished Board Thickness |

L≤2L: 0.15mm; 4L: 0.4mm |

Maximum Finished Board Thickness |

10.0 mm |

Blind Buried Holes (Non-crossing) |

0.1mm |

Maximum Hole Aspect Ratio |

15:01 |

Minimum Mechanical Drill Hole Diameter |

0.1 mm |

Through-hole Tolerance |

+/- 0.0762 mm |

Press-fit Hole Tolerance |

+/- 0.05mm |

Non-plated Copper Hole Tolerance |

+/- 0.05mm |

Maximum Number of Layers |

32 |

Internal and External Layer Maximum Copper Thickness |

12Oz |

Minimum Drill Hole Tolerance |

+/- 2mil |

Minimum Layer-to-Layer Tolerance |

+/- 3mil |

Minimum Line Width/Spacing |

3mil/3mil |

Minimum BGA Diameter |

8mil |

Impedance Tolerance |

< 50Ω ±5Ω; ≥50Ω±10% |

Surface Treatment Processes |

Leaded/Lead-free HASL, Immersion Gold, Immersion Silver, Immersion Tin, OSP, ENIG, ENEPIG, Pure gold, Carbon Ink, Peelable Mask, Gold Finger, etc. |

|

|

|

|

|

|

Hot Tags:

RO4350B Dielectric Constant |

Rogers 6-layer Hybrid PCB |

Immersion Gold Plating |

20mil RO4350B Core and FR-4 Material |

Hybrid Substrate for RF Switches |

|

|

|