|

|

|

|

|

|

|

2-layer-SF305-Adhesive-Polyimide-0.15mm-Thick-Plated-Through-Hole-Flexible-Printed-Circuit-(FPC)-from-Shengyi |

|

|

(FPC’s are custom-made products. The picture and parameters shown are for reference only.) |

|

|

|

|

|

General description of Shengyi SF305 PCB |

|

|

This flexible printed circuit (FPC) utilizes standard SF305 Adhesive Polyimide material specifically designed for Wi-Fi antenna applications. The construction features a 2-layer flexible board with a 0.15mm thickness. The design incorporates yellow coverlay serving as solder mask across the entire board surface, with no silkscreen applied. All contact pads receive immersion gold (ENIG) surface treatment. The connector area is reinforced with polyimide stiffener material. Manufactured using Shengyi base SF305 laminate material, these FPCs are produced in compliance with IPC 6012 Class 2 specifications based on customer-supplied Gerber data. Finished products are packaged in quantities of 200 units per shipment. |

|

|

|

|

|

SF305 FPC Specifications |

|

|

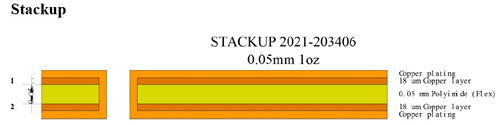

Number of Layers |

Double sided |

Outline Dimension |

21.15 x 58.93mm = 1PCS |

Board Type |

Flexible Circuit |

Board Thickness |

0.15mm +/-10% |

Board Material |

Polyimide (PI) 50 um |

Board Material Supplier |

Shengyi |

Tg Value of Board Material |

60℃ |

|

PTH Cu thickness |

≥20 um |

Inner Iayer Cu thicknes |

N/A |

Surface Cu thickness |

35 um (1oz) |

|

Coverlay Colour |

Yellow |

Number of Coverlay |

2 |

Thickness of Coverlay |

25 um |

Stiffener |

200 um |

|

Type of Silkscreen Ink |

IJR-4000 MW300 |

Supplier of Silkscreen |

TAIYO |

Color of Silkscreen |

White |

Number of Silkscreen |

1 |

|

Mininum Trace (mil) |

4 mil |

Minimum Gap(mil) |

4 mil |

|

Surface Finish |

Immersion Gold |

RoHS Required |

Yes |

Famability |

94-V0 |

|

Thermal Shock Test |

Pass, -25℃±125℃, 1000 cycles. |

Thermal Stress |

Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

Function |

100% Pass electrical test |

Workmanship |

Compliance with IPC-A-600H & IPC-6013C Class 2 |

|

|

|

|

|

|

.jpg) |

|

|

|

|

|

Features and Benefits

1. Excellent flexibility

2. Reducing the volume

3. Weight reduction

4. 8000 types of PCB per month

5.Quick CADCAM checking and free PCB quotation

6. No minimum order quantity. 1 piece is available

7. Volume Production capability

8. On-time service

9. More than 20 years of experience |

|

|

Applications |

|

|

Keypad FPC; Toy lamp strip; Display backlight; Flex keyboard for mobile phone keys; POS antenna soft board; LCD TV soft board; Digital camera soft board. |

|

|

|

|

|

Parameters (SF305) |

|

|

Test Item |

Test Method |

Unit |

IPC

Standard |

Typical Value |

|

|

|

|

SF305

051813DR |

SF305

051813SE |

Peel Strength 90° |

IPC-TM-650,No.2.4.9

Method A

Method C |

N/mm |

≥0.7

≥0.525 |

1.1

1.0 |

1.3

1.2 |

Thermal Stress |

IPC-TM-650,No.2.4.13 |

- |

Pass |

Pass |

|

Dimensional Stability |

IPC-TM-650,No.2.2.4

Method B |

% |

±0.15 |

MD: -0.0684

TD: 0.0691 |

MD: -0.0418

TD: 0.0354 |

Chemical Resistance |

IPC-TM-650,No.2.3.2 |

% |

≥80 |

>85 |

>85 |

Moisture Absorption |

IPC-TM-650,No.2.6.2 |

% |

≤4 |

1.46 |

1.37 |

Volume Resistivity |

IPC-TM-650,No.2.5.17 |

MΩ-cm |

≥10^6 |

1.5×10^8 |

2.0×10^8 |

Surface Resistance |

IPC-TM-650,No.2.5.17 |

MΩ |

≥10^5 |

5.0×10^6 |

4.5×10^6 |

Dielectric Constant 10GHZ |

IEC-61189-2-721 |

- |

- |

3.34 |

3.31 |

Dissipation Factor 10GHZ |

IEC-61189-2-721 |

- |

- |

0.0191 |

0.0188 |

Dielectric Strength |

IPC-TM-650,No.2.5.6.1 |

V/μm |

≥80 |

134 |

140 |

Folding Endurance (MIT method) |

R0.38×4.9N,with cvl |

Times |

- |

>2000 |

>1000 |

|

|

|

|

|

|

Double-Sided Flexible Circuits |

|

|

Flexible circuits derive their name from their characteristic thin, pliable substrate material with copper foil laminated on both surfaces. These double-sided circuits typically incorporate protective coverlays permanently bonded to the exterior copper layers on each side. Unlike rigid boards, the conductive through-holes in these flexible designs are predominantly formed by precision drilling rather than mechanical punching processes. Standard manufacturing practice includes the application of coverlay films on both circuit surfaces as a protective measure. |

|

|

|

|

|

|

|

|

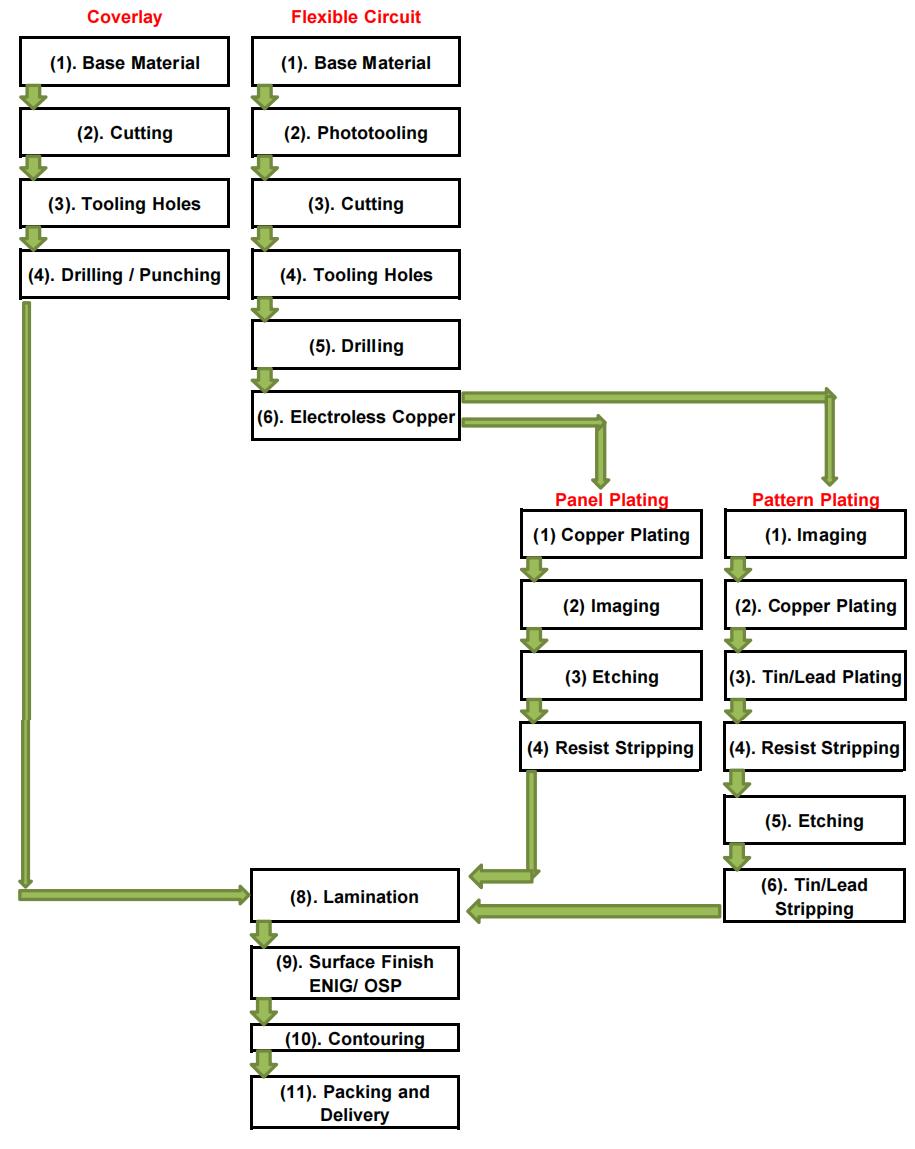

Manufacturing Process of Double Sided FPC |

|

|

The production of double-sided plated-through-hole (PTH) flexible PCBs shares certain similarities with single-sided non-plated boards, yet involves distinct manufacturing steps executed in a modified sequence. The following outlines the specialized fabrication process for double-sided flexible circuits. |

|

|

|

|

|

|

More Displays of Double Sided FPC |

|

.jpg) |

|

|

|

.jpg) |

|

|

|

|

|

|

|

|

|

Hot Tags:

SF305 PCB for Wi Fi Antenna |

0.15mm SF305 Laminate |

2-layer Flexible Board |

SF305 Adhesive Polyimide PCB |

Shengyi Double Sided FPC |

|

|