|

|

|

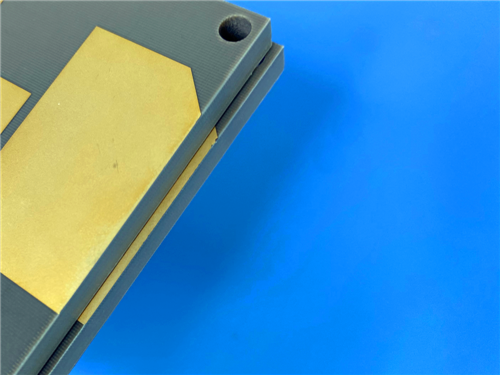

2-layer-250mil-6.35mm-Thick-Wangling-F4BTMS220-High-Frequency-PCB-with-Low-DF-0.0010-for-Aerospace |

|

|

|

|

|

|

|

1. F4BTMS Introduction

The F4BTMS series represents a groundbreaking upgrade to the F4BTM series, achieving significant advancements in material formulation and manufacturing processes. Enriched with a high ceramic content and reinforced with ultra-thin, ultra-fine glass fiber cloth, this material delivers superior performance and a wider range of dielectric constants. Designed for high-reliability applications, the F4BTMS series is an ideal choice for aerospace and can seamlessly replace similar foreign products.

|

|

|

|

By integrating a unique blend of ultra-thin glass fiber cloth and specially formulated nano-ceramics with polytetrafluoroethylene resin, the F4BTMS series minimizes the negative impact of glass fibers on electromagnetic wave propagation. This innovative composition reduces dielectric loss, enhances dimensional stability, and decreases X/Y/Z anisotropy. The result is a material with an extended usable frequency range, improved electrical strength, and superior thermal conductivity. Additionally, the F4BTMS series boasts a low thermal expansion coefficient and stable dielectric temperature characteristics, ensuring consistent performance in demanding environments. |

|

|

|

The F4BTMS series comes standard with RTF low roughness copper foil, which reduces conductor loss and provides excellent peel strength. Compatible with both copper and aluminum bases, this material is a versatile and reliable solution for high-frequency applications. Whether for aerospace, telecommunications, or advanced electronics, the F4BTMS series sets a new standard for performance and durability. |

|

|

|

2. Features of F4BTMS220:

- Dielectric constant (Dk) of 2.2 at 10GHz

- Dissipation factor of .0009 at 10GHz, 0.0010 at 20GHz

- CTE x-axis of 40 ppm/°C, CTE y-axis of 50 ppm/°C, CTE z-axis of 290 ppm/°C, -55°C to 288°C

- Low thermal coefficient of Dk at-130 ppm/°C, -55°C to 150°C

- UL-94 V0

- Low Moisture absorption of 0.02%

|

|

|

|

3. PCB Stackup: 2-layer rigid PCB

Copper_layer_1 - 35 μm

F4BTMS220 Core - 6.35 mm (250mil)

Copper_layer_2 - 35 μm |

|

| 4. PCB Construction Details: |

| |

| - Board dimensions: 75mm x 75mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 5/9 mils

- Minimum Hole Size: 0.6mm

- No Blind vias.

- Finished board thickness: 6.4mm

- Finished Cu weight: 1oz (1.4 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Pure gold

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment |

| |

|

|

|

|

5. PCB Statistics:

Components: 8

Total Pads: 20

Thru Hole Pads: 12

Top SMT Pads: 8

Bottom SMT Pads: 0

Vias: 23

Nets: 2

|

|

|

|

6. Type of artwork supplied: Gerber RS-274-X |

|

|

|

7. Quality standard: IPC-Class-2 |

|

|

|

8. Availability: worldwide |

|

|

|

9. Some Typical Applications:

- Aerospace equipment, including space and cabin systems.

- Microwave and RF technologies.

- Military and commercial radar systems.

- Feed networks for various applications.

- Phase-sensitive and phased array antennas.

- Satellite communications. |

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: 12.9mm-Thick-Wangling-F4BTMS1000-PCB: 4-Layer-Aerospace-Material-with-Enhanced Dielectric-Properties-and-Superior-Thermal-Conductivity |

|

|

|

|

|

|