| |

|

|

|

|

|

|

|

|

1.0mm-4-Layer-Mixed-Hybrid-PCB-with-High-Quality-4mil-Rogers-RO4350B-and-0.3mm-High-Tg-FR-4 |

|

|

|

|

|

(As PCBs are custom - produced goods, the picture and parameters shown are only intended for reference.) |

|

|

|

|

|

Hello, everyone!

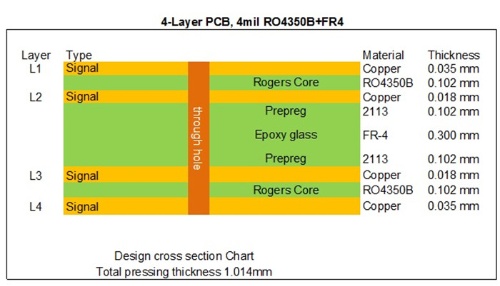

Today, we'll be discussing a 4-layer high-frequency PCB that combines 4mil RO4350B and FR-4 materials. The 4-layer configuration of this PCB was chosen for its simplicity and cost-effectiveness, which is crucial for entering new markets.

Now, let's start by examining the initial build-up process. |

|

|

|

|

|

|

|

|

|

|

|

Between the first and second layers, as well as the third and fourth layers, we use the Rogers core, specifically 4mil (0.102mm) RO4350B. This core has a fixed thickness, which plays a crucial role in determining the electrical length of the RF lines on the circuit board. Sandwiched in the middle is the FR - 4 epoxy glass dielectric material. It serves to bond the cores on both the top and bottom sides. The inner layer of the PCB has a copper weight of 0.5 ounces, while the outer layer has a copper weight of 1 ounce.

|

|

|

|

|

Now, let's delve into the detailed specifications of this board:

Base material: RO4350B 0.102mm + Tg 170℃ FR4 0.30mm

Layer count: 4 layers

Panel: 55mm x 132mm = 1 type = 1 piece

Surface finish: Immersion gold

Copper weight: Outer layer 35 um/ Inner layer 18 um

Solder mask / Legend: green / white

Final PCB height: 1.0 mm

Special technology: via in pad (hole filled) under BGA

Standard: IPC 6012 Class 2

Packing: 25 panels are packed for shipment.

Lead time: 12 working days

Shelf life: 6 months |

|

|

|

|

|

|

|

This 4-layer high-frequency PCB combines 4mil RO4350B and FR-4 materials, offering a simple and cost-effective solution ideal for entering new markets. The RO4350B hybrid PCB is widely used in applications such as preamplifiers, radar sensors, digital transmitters, and splitter modules; GPS antennas, communication relays, analog transmitters, and 4G antennas; as well as RF transmitters, WiFi amplifiers, RFID systems, and attenuators. |

|

|

|

The advantages of RO4350B hybrid PCBs: |

|

|

1. Stable Dielectric Constant:

RO4350B maintains a consistent dielectric constant across a wide frequency range, making it an excellent choice for broadband applications.

2. Enhanced Signal Integrity:

It outperforms stack-ups using only FR4 materials, ensuring superior signal performance.

3. Cost Efficiency:

By combining RO4350B with other materials, it offers a more cost-effective solution compared to all low-loss material stack-ups.

4.Reduced High-Frequency Signal Loss:

It minimizes signal loss at high frequencies, ensuring reliable performance in demanding applications.

5. Expert Manufacturing Support:

Leverage our robust capabilities, from prototyping to mass production, backed by IATF 16949 (2016), ISO14001 (2015), ISO9001 (2015), and UL certifications, guaranteeing top-tier quality for your PCBs. |

|

|

|

|

|

That concludes today’s update. Thank you for your time, and feel free to reach out to us for any RF PCB inquiries—we’re here to assist! |

|

|

|

|

|

Appendix: Our PCB Capability 2022 |

|

|

Parameter |

Value |

Layer Counts |

1-32 |

Substrate Material |

RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5; PTFE F4B (DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2); AD450, AD600, AD1000, TC350; Nelco N4000, N9350, N9240; FR-4 ( High Tg S1000-2M, TU-872 SLK, TU-768, IT-180A etc.), FR-4 High CTI>600V; Polyimide, PET; Metal Core etc. |

Maximum Size |

Flying test: 900*600mm, Fixture test 460*380mm, No test 1100*600mm |

Board Outline Tolerance |

±0.0059" (0.15mm) |

PCB Thickness |

0.0157" - 0.3937" (0.40mm--10.00mm) |

Thickness Tolerance(T≥0.8mm) |

±8% |

Thickness Tolerance(t<0.8mm) |

±10% |

Insulation Layer Thickness |

0.00295" - 0.1969" (0.075mm--5.00mm) |

Minimum Track |

0.003" (0.075mm) |

Minimum Space |

0.003" (0.075mm) |

Outer Copper Thickness |

35µm--420µm (1oz-12oz) |

Inner Copper Thickness |

17µm--350µm (0.5oz - 10oz) |

Drill Hole(Mechanical) |

0.0059" - 0.25" (0.15mm--6.35mm) |

Finished Hole(Mechanical) |

0.0039"-0.248" (0.10mm--6.30mm) |

DiameterTolerance(Mechanical) |

0.00295" (0.075mm) |

Registration (Mechanical) |

0.00197" (0.05mm) |

Aspect Ratio |

12:1 |

Solder Mask Type |

LPI |

Min Soldermask Bridge |

0.00315" (0.08mm) |

Min Soldermask Clearance |

0.00197" (0.05mm) |

Plug via Diameter |

0.0098" - 0.0236" (0.25mm--0.60mm) |

Impedance Control Tolerance |

±10% |

Surface Finish |

HASL,HASL LF,ENIG,Immersion Tin,Immersion Silver, OSP, Gold Finger, Pure gold plated etc. |

|

|

|

|

|

|

Hot Tags:

Rogers RO4350B Substrate |

Rogers RO4350B for Sale |

4mil RO4350B Thickness |

RO4350B Loss Tangent |

RO4350B Hybrid PCB |

|

|

|