Home

-

High frequency PCB

-

Rogers RO4003C Multilayer PCB 4-Layer 4.8mm Thick Rogers 4003C High Frequency Printed Circuit Board

Home

-

High frequency PCB

-

Rogers RO4003C Multilayer PCB 4-Layer 4.8mm Thick Rogers 4003C High Frequency Printed Circuit Board

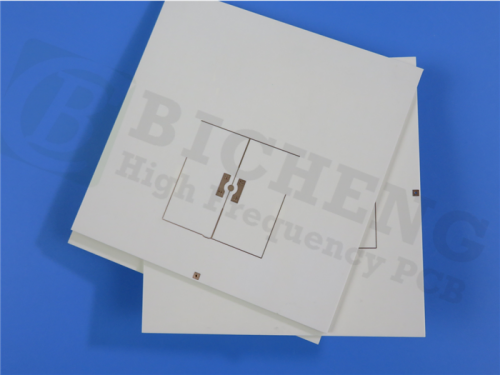

Rogers RO4003C Multilayer PCB 4-Layer 4.8mm Thick Rogers 4003C High Frequency Printed Circuit Board

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Introduction

The RO4003C Multilayer PCB is a groundbreaking circuit board that combines the electrical performance of PTFE/woven glass with the manufacturability of epoxy/glass. Developed by Rogers Corporation, a leading name in advanced materials for high-frequency electronic applications, the RO4003C material offers exceptional performance at competitive prices.

The RO4003C Advantage

The Rogers RO4003C High Frequency PCB material exhibits low dielectric loss, making it an excellent choice for applications with higher operating frequencies where conventional laminates fall short. Featuring a proprietary woven glass reinforced hydrocarbon/ceramic composition, Rogers RO4003C provides an unmatched combination of dielectric properties and manufacturing ease. This enables designers to achieve superior high-frequency performance while benefiting from the cost-efficiency of standard epoxy/glass processes.

Features of RO4003C

RO4003C substrate possesses several key features that ensure excellent performance in high-frequency applications:

- The dielectric constant of RO4003C is precisely controlled at 3.38 +/-0.05 at 10GHz, ensuring stable electrical characteristics.

- With a low dissipation factor of 0.0027 at 10GHz, RO4003C minimizes energy loss, ensuring efficient signal propagation.

- RO4003C exhibits a thermal conductivity of 0.71 W/m/°K, dissipating heat effectively and maintaining circuit reliability.

- The thermal coefficient of dielectric constant ranges from -50°C to 150°C, with a value of +40 ppm/°C. This feature ensures consistent electrical performance over a wide temperature range.

- RO4003C has a CTE (Coefficient of Thermal Expansion) matched to copper, ensuring dimensional stability and reliability in harsh thermal environments. The X-axis CTE is 11ppm/°C, while the Y-axis is 14ppm/°C.

- The low Z-axis coefficient of thermal expansion, measured at 46 ppm/°C, reduces stress on the board and increases its longevity.

PCB Stackup and Specifications

The RO4003C PCB is designed as a 4-layer Multilayer PCB with the following stackup:

| PCB SIZE | 84 x 78mm=1PCS |

| BOARD TYPE | RF PCB, Microwave PCB |

| Number of Layers | Double sided PCB |

| Surface Mount Components | YES |

| Through Hole Components | YES |

| LAYER STACKUP | copper ------- 35um(1oz)+PLATE |

| RO4003C 60mil | |

| copper ------- 35um(1oz)+PLATE | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 10mil/12mil |

| Minimum / Maximum Holes: | 0.3/2.3mm |

| Number of Different Holes: | 4 |

| Number of Drill Holes: | 155 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | NO |

| BOARD MATERIAL | |

| Glass Epoxy: | RO4003C 60mil, Tg 288℃ |

| Final foil external: | 1.5oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 1.6mm ±0.16 |

| PLATING AND COATING | |

| Surface Finish | Electroless nickel over Immersion Gold (ENIG)( 2 µ" over 100 µ" nickel) |

| Solder Mask Apply To: | no Solder mask reqruied |

| Solder Mask Color: | no solder mask required |

| Solder Mask Type: | no solder mask reqruied |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | no silkscreen required |

| Colour of Component Legend | no silkscreen required |

| Manufacturer Name or Logo: | no silkscreen required |

| VIA | Plated Through Hole(PTH) |

| FLAMIBILITY RATING | N/A |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

PCB Statistics

The PCB statistics pertain to a 4-layer board with a 4.8mm thickness, fabricated using Rogers 4003C laminate material.

| RO4003C Typical Value | |||||

| Property | RO4003C | Direction | Units | Condition | Test Method |

| Dielectric Constant,εProcess | 3.38±0.05 | Z | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline | |

| Dielectric Constant,εDesign | 3.55 | Z | 8 to 40 GHz | Differential Phase Length Method | |

| Dissipation Factortan,δ | 0.0027 0.0021 |

Z | 10 GHz/23℃ 2.5 GHz/23℃ |

IPC-TM-650 2.5.5.5 | |

| Thermal Coefficient of ε | +40 | Z | ppm/℃ | -50℃to 150℃ | IPC-TM-650 2.5.5.5 |

| Volume Resistivity | 1.7 x 1010 | MΩ.cm | COND A | IPC-TM-650 2.5.17.1 | |

| Surface Resistivity | 4.2 x 109 | MΩ | COND A | IPC-TM-650 2.5.17.1 | |

| Electrical Strength | 31.2(780) | Z | Kv/mm(v/mil) | 0.51mm(0.020") | IPC-TM-650 2.5.6.2 |

| Tensile Modulus | 19,650(2,850) 19,450(2,821) |

X Y |

MPa(ksi) | RT | ASTM D 638 |

| Tensile Strength | 139(20.2) 100(14.5) |

X Y |

MPa(ksi) | RT | ASTM D 638 |

| Flexural Strength | 276 (40) |

MPa (kpsi) |

IPC-TM-650 2.4.4 | ||

| Dimensional Stability | <0.3 | X,Y | mm/m (mil/inch) |

after etch+E2/150℃ | IPC-TM-650 2.4.39A |

| Coefficient of Thermal Expansion | 11 14 46 |

X Y Z |

ppm/℃ | -55℃to288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | ℃ TMA | A | IPC-TM-650 2.4.24.3 | |

| Td | 425 | ℃ TGA | ASTM D 3850 | ||

| Thermal Conductivity | 0.71 | W/M/oK | 80℃ | ASTM C518 | |

| Moisture Absorption | 0.06 | % | 48hrs immersion 0.060" | ||

| sample Temperature 50℃" | ASTM D 570 | ||||

| Density | 1.79 | gm/cm3 | 23℃ | ASTM D 792 | |

| Copper Peel Stength | 1.05 (6.0) |

N/mm (pli) |

after solder float 1 oz. EDC Foil |

IPC-TM-650 2.4.8 | |

| Flammability | N/A | UL 94 | |||

| Lead-free Process Compatible | Yes |

Application

Due to its excellent high-frequency performance and stable electrical properties, RO4003C PCBs are widely used in the following fields:

- Wireless communication base stations and antenna systems

- Satellite communication and radar equipment

- RF/microwave components and modules

- High-frequency testing and measurement equipment

- Aerospace and military electronic systems

- High-speed digital circuits and signal processing

Conclusion

In conclusion, the RO4003C multilayer circuit boards combines superior electrical performance with low-cost circuit fabrication. With its exceptional dielectric properties, thermal stability, and controlled impedance characteristics, it is the ideal choice for high-frequency applications where performance and reliability are critical. Whether it's commercial avionics, advanced radar systems, or next-generation wireless communications, the Rogers 4003C PCB offers the reliability and performance needed to drive innovation in the modern electronics industry.